How do I prevent sample evaporation when using the Plate Reader?

Introduction

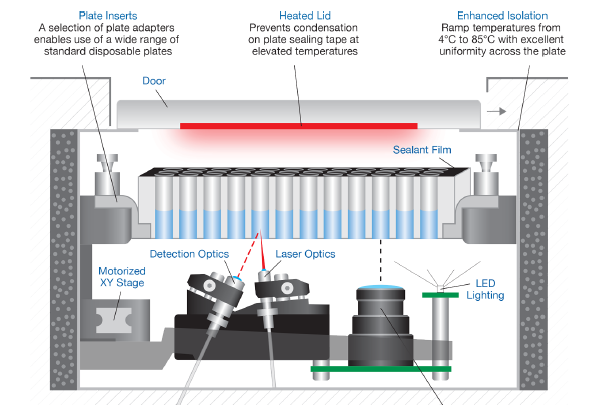

Evaporation can be a serious issue for measurements performed in a DynaPro Plate Reader III over long time periods or high temperatures. If you are using a 1536-well plate, samples may evaporate in as little as a half hour due to the low well volumes. Evaporation can change the concentration of your samples as well as drop the sample level below the laser-detector beam intersection of the Plate Reader. While increasing the concentration may improve the data at first due to a stronger autocorrelation signal, when the sample level drops below the beam you will no longer be able to collect useful data.

To prevent evaporation, you can apply oil or sealant film to the top of your samples. Sealant film is ideal for when you would like to recover your samples after a study for further characterization.

Covering with Oil

When using oil, the exact volume is not important as long as the sample meniscus is covered. A standard oil volume is 20 µL for a 384-well plate and 5 µL and for a 1536-well plate. We recommend either paraffin oil (IR spectroscopy grade; Sigma-Aldrich p/n 76235) or silicon oil (for oil baths, usable from -40 to +200°C; Alfa Aesar p/n A12728). Check that your sample is not affected by the oil before applying.

Note: Do not use paraffin oil to cover well plates made from cycloolefin polymer or copolymer (COP or COC).

Applying Sealant Film

A new feature of the DynaPro Plate Reader III is a heated lid that provides a gentle thermal gradient to prevent condensation on the sealant film and provide high quality data.

Using sealing tape with a Plate Reader II may be more challenging since without the heated lid solvent might evaporate and condense on the tape, potentially affecting data quality.

When using a sealing tape, fill the wells with more than the specified minimum volume (1.5 to 2.5 times) in case there is any evaporation. Don’t cover the well plate with opaque tapes or lids while measuring as they can interfere with data collection. Also, don’t use plastic lids as they may cause damage to moving parts of the Plate Reader due to the increased height. Make sure to go over the sealing tape with the supplied applicator to apply an even pressure along the film. Improper application can compromise the optical performance of the Plate Reader III.

The Plate Reader III ships with several pre-cut sealing tapes (Nunc Sealing Tape, polyolefin silicone, -40°C to + 90°C (Wyatt p/n S8810-235307) and a hand-held applicator (Wyatt p/n P8810-250050). If you need additional sealing tape you can order a case of 100 precut Nunc Sealing Tapes from Thermo Fisher (p/n 235307) or Wyatt (p/n 900150). The applicator can be purchased separately as well, Thermo Fisher (p/n 250050) for 2 or Wyatt (p/n P8810-250050) for 1.

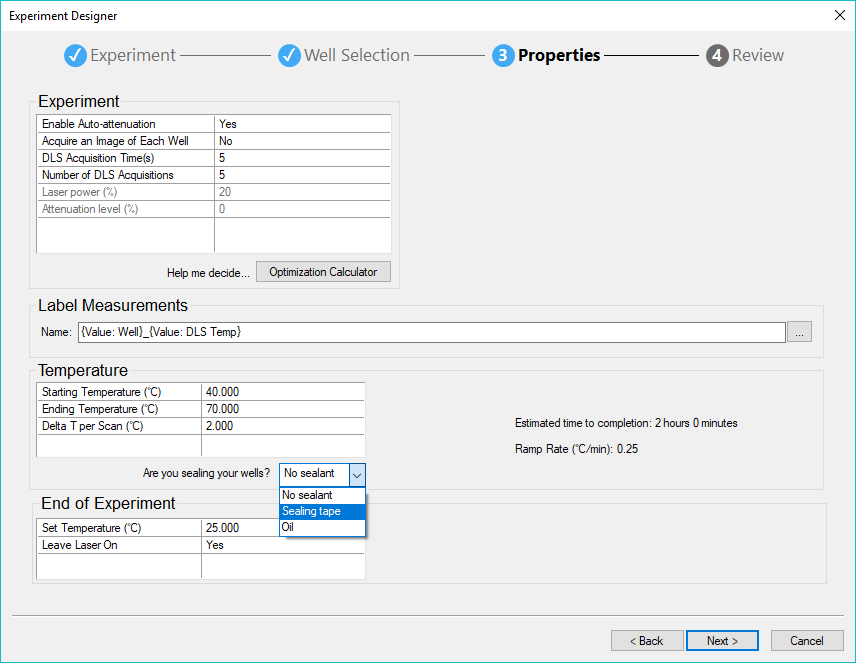

Configuring DYNAMICS for a Sealant

If you are using oil or a sealant film, be sure to set this in your DYNAMICS experiment. In Experiment Designer, choose the sealant type (No Sealant, Sealing tape, or Oil) from the pulldown menu.

If you are using an Event Schedule instead of Experiment Designer, you can set this in Parameters | Instrument. Choosing “Sealing tape” activates the Plate Reader III heated lid to prevent condensation on the film.

Conclusion

The Wyatt Support Center has a list of compatible microwell plates for all models of the Plate Reader under Instrument Support. Because the Plate Reader III adds the capability of performing static light scattering (SLS), the list also recommends optimal plates for SLS measurements with sealing tape. We offer a video tutorial showing how to correctly apply sealing tape under Instrument Tutorials on the Support Center.

Do you have a question? Contact our experts here in Customer Support. We’re happy to help! Call +1 (805) 681-9009 option 4 or email support@wyatt.com.