How do the new fixed-height channels make it easier to run my FFF experiments?

Introduction

The separation channel is an essential component of asymmetric flow field-flow fractionation (AF4 or simply FFF). Analogous to the column in size-exclusion chromatography (SEC), the chromatographic separation takes place in a trapezoidal channel in FFF. With the lack of a stationary phase, lower surface area and gentler shear forces, the FFF channel is ideally suited for the separation of large particles and polymers that may not elute properly from an SEC column.

Variable-height channels: flexible and established configuration

Typically, an interchangeable spacer made out of a polymeric material is used to determine the height of the interior channel. Channel height is an important parameter when optimizing FFF separations. Increasing the channel height will improve resolution and increase sample retention time assuming all other experimental parameters remain the same. Spacers of variable thicknesses, typically in the range of 250 to 900 µm, are available.

This widely-used variable-height channel design offers excellent flexibility for method development and highly diverse applications in research labs. Users may frequently swap between spacers of different thicknesses to optimize their separation conditions.

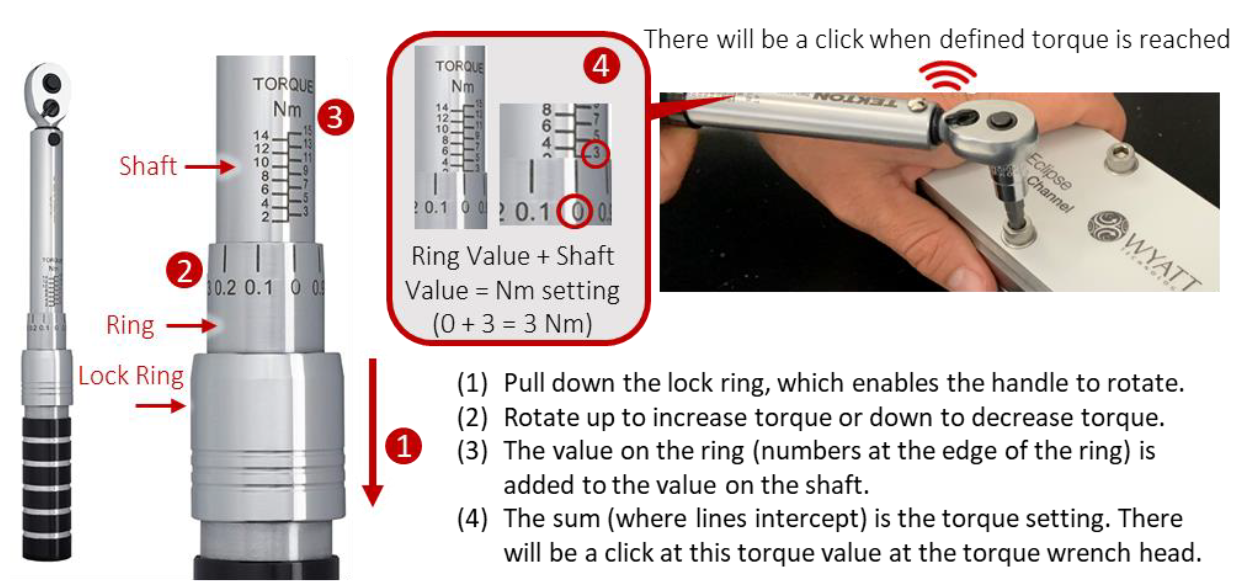

However, this flexibility comes with some drawbacks. A user must assemble the channel correctly and use a torque wrench for proper sealing. The spacer itself is considered a consumable meant to be swapped with every membrane change. Spacers will also compress up to 100 µm under full channel torque, resulting in a smaller effective channel height than expected by theory or simulations in VISION DESIGN™ (without channel height correction).

Fixed-height channels: added convenience with excellent reproducibility

In the new fixed-height channels, the spacer is integrated into the top plate. Changing “spacers” is accomplished by swapping the entire top block for another one of different channel height. This design simplifies the channel assembly significantly since a researcher can now use a hex screwdriver rather than a torque wrench. It also reduces membrane compression to ~25 µm as the stainless top and bottom blocks are in direct contact with each other, leading to little change in actual channel height.

The fixed-height channel is ideal for routine and QC applications. The lack of a spacer made out of polymeric material also makes it the preferred choice for applications in organic mobile phases.

Fixed-height channel top blocks with heights of 250, 350 and 500 µm are available for the Short and Long Channel configurations, roughly equivalent to the effective heights of the variable-height spacers. The Semi-Prep channel comes with top block heights of 400, 525, 650, and 900 µm. These channel heights maintain approximately the same separation profile as the spacers in the flexible height channels.

The fixed height channel tops are durable but require a higher initial investment than the disposable spacers that are used with the flexible-height channels.

Which channel type should I use?

It depends! The fixed-height channel is an excellent choice if you’ve already established a routine FFF method for your applications, want the easiest channel assembly with and highest reproducibility of your sample runs, use organic solvents or solvent mixtures, and don’t mind higher costs for additional top blocks. The variable-height channel is the ideal choice if you’re frequently switching projects, conditions and work primarily with unknown samples.

Tip: Use VISION DESIGN to develop flow conditions and selecting channel heights in silico before running your samples.

Conclusion

To learn more about what you can do with FFF, log into our Support Center for resources including application notes, technical notes, and white papers.

Do you have a question? Contact our experts here in Customer Support. We’re happy to help! Call +1 (805) 681-9009 option 4.