Real-Time MALS

Real-time multi-angle light scattering = RT-MALS for PAT

RT-MALS takes the power of MALS and dynamic light scattering (DLS) out of the analytical laboratory and integrates it in-line or on-line with process equipment such as prep-LC or TFF. As a real-time PAT, it is used to develop, monitor and control downstream processes for many modalities including viral vectors, nanoparticles, recombinant proteins, nucleic acids and biopolymers.

RT-MALS is implemented with an ultraDAWN™ MALS instrument and OBSERVER™ software. It provides key product attributes, such as molar mass, radius, particle concentration, polydispersity, viral titer and empty-full ratio, up to five times per second. The real-time data are used to indicate a process endpoint, collect the appropriate pool or flag deviations from acceptable product attribute values.

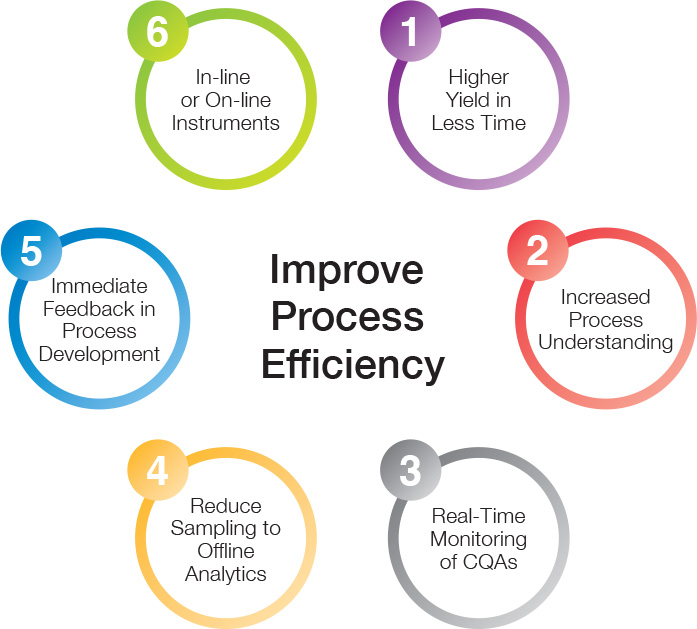

Benefits of RT-MALS:

- Accelerate process development and scale-up

- Increase yield, reduce overall time until lot release

- Maintain product quality with confidence

What is RT-MALS?

RT-MALS adds multi-angle light scattering instrumentation and real-time software to process equipment such as preparative chromatography, tangential flow filtration, homogenizers, reactors or nanoparticle production systems. It is a powerful technique for monitoring attributes of macromolecules, nanoparticles and small gene vectors like AAV in terms of:

- Molar mass

- Size

- Particle concentration or titer

- Full:total capsid ratio

The addition of a WyattQELS™ embedded DLS module enables measurement of even more attributes:

- Hydrodynamic radius

- Polydispersity index

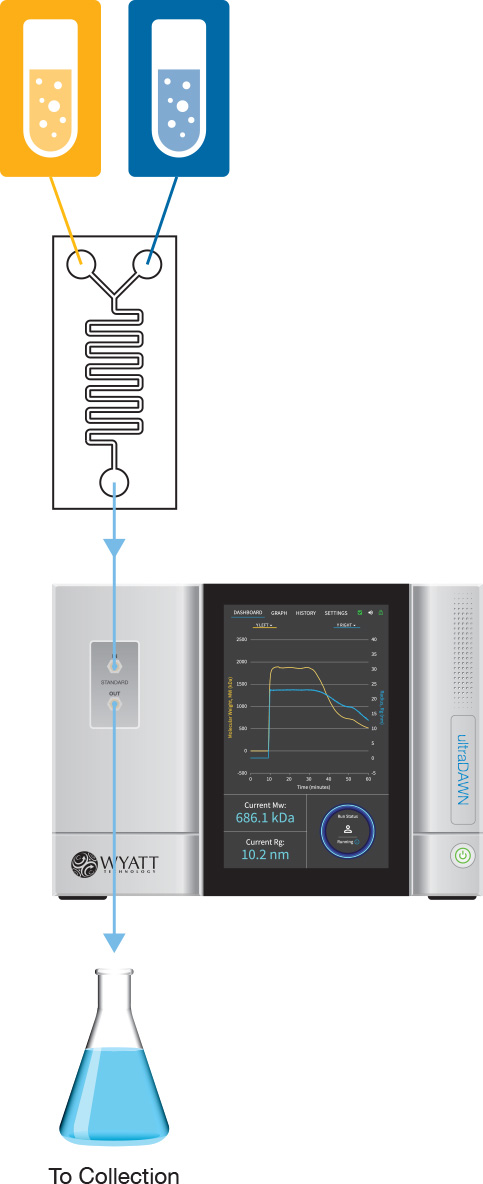

The process is sampled continuously or periodically. For bench- to pilot-scale preparative chromatography and nanoparticle formulation providing inherent flow, operation is fully in-line: the entire process stream passes through the ultraDAWN and continues on through the process equipment.

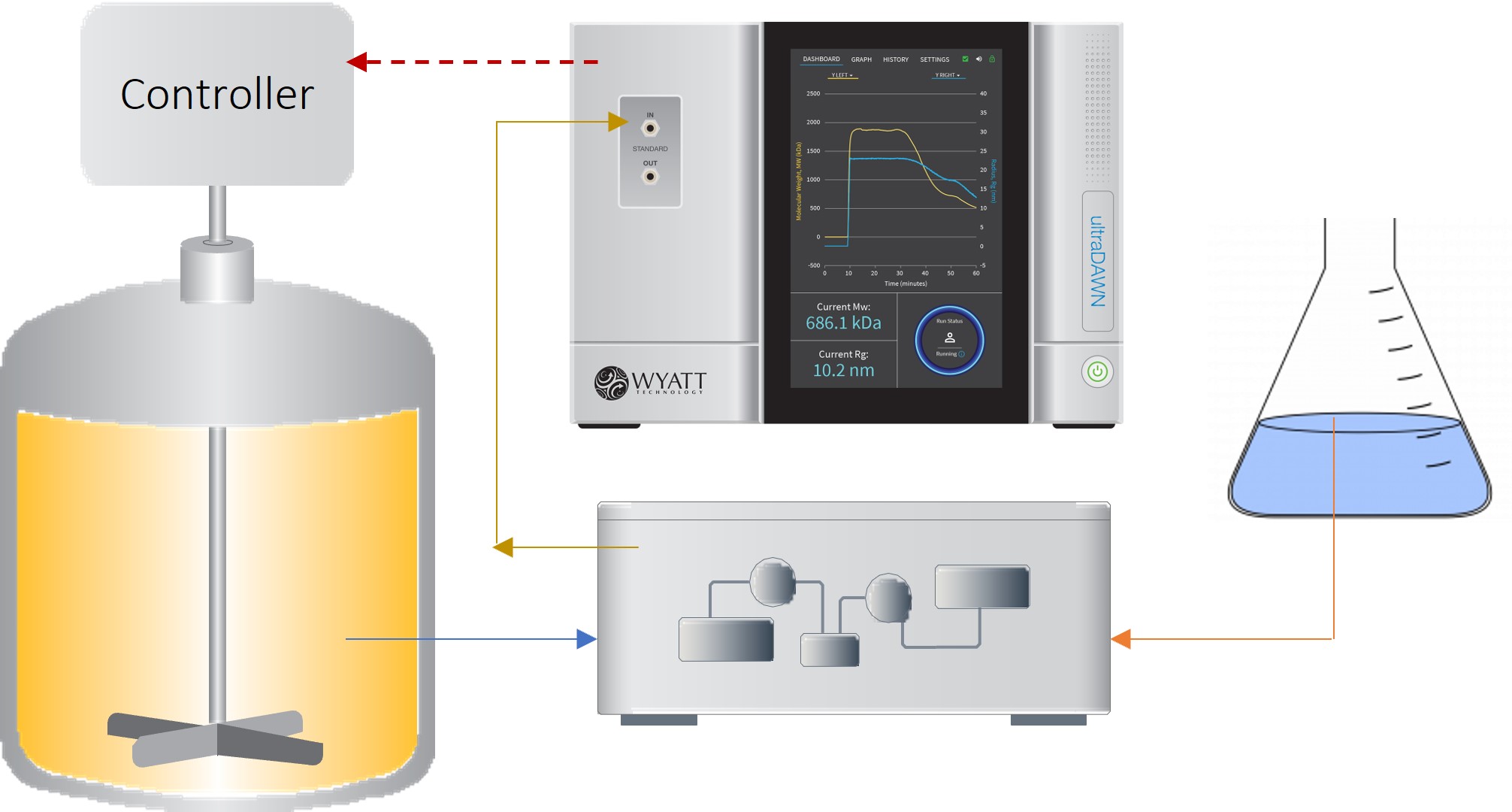

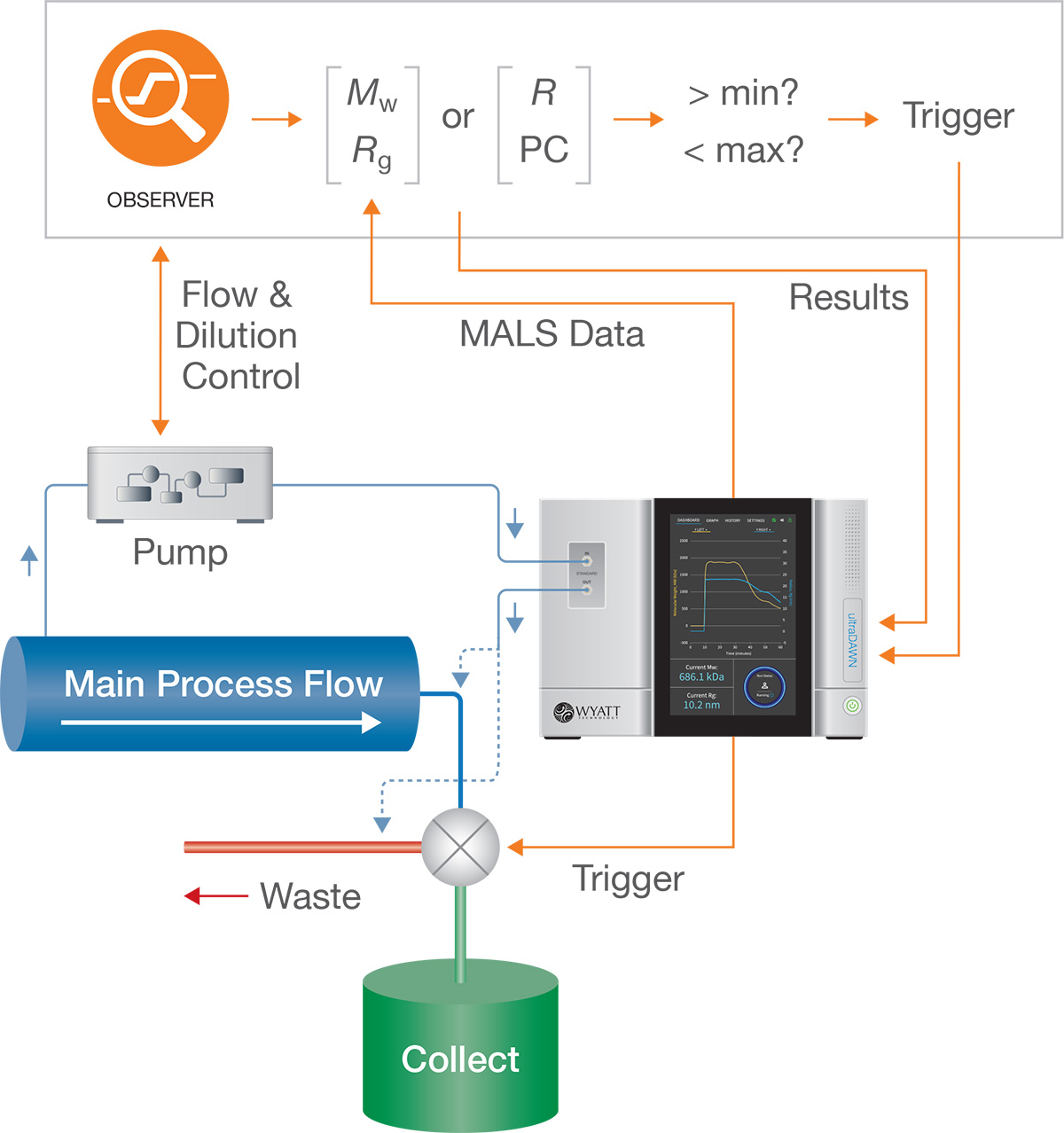

For production-scale flow rates, or for sampling from static vessels like a reactor or UF/DF reservoir, operation is on-line: an auxiliary pump continuously draws off a small fraction of the product and delivers it to the ultraDAWN, optionally diluting up to 20x. While the total amount of sample used for on-line analytics is low, often it may be recycled to the process.

The MALS and DLS signals, (and sometimes UV or dRI) are analyzed to quantify the analyte’s physical properties. Measurements may be made up to 5 times per second for rapid feedback and process control.

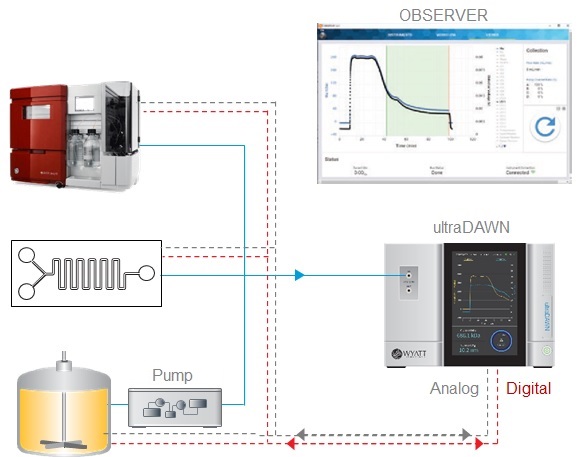

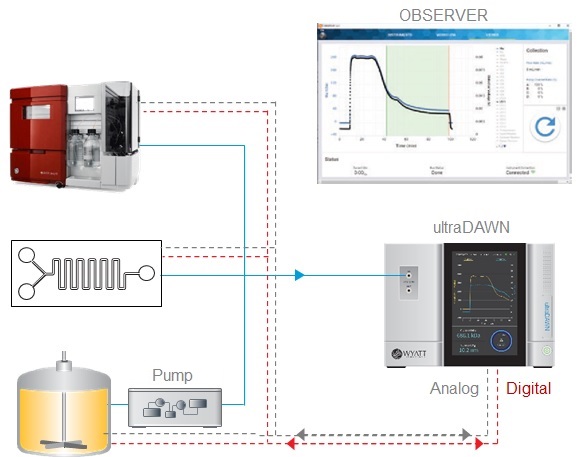

An ultraDAWN may be added as a PAT tool in-line or on-line (using an auxiliary pump). OBSERVER software controls the ultraDAWN and pump, providing feedback to the process via analog or digital signals.

Why RT-MALS?

Key product attributes, no waiting

Traditionally, determination of product attributes means collecting aliquots, sending them off to the analytical lab, and waiting for results – for hours, days or even weeks. In process development, this delay slows down optimization, adds unnecessary development runs and increases time to market. In the manufacturing plant it impacts productivity, and can be especially painful when deviations are only caught during final QC.

RT-MALS monitors critical quality attributes (CQAs) and other properties directly, for rapid feedback on product and process quality. It quantifies size, molecular weight, particle concentration, capsid titer, polydispersity and capsid content, and signals the process controller when the values meet or deviate from specified ranges. Instead of waiting for the results, product attribute data are provided on time scales of just seconds or tens of seconds. The outcome: faster, more effective process development and tighter control over production processes.

Aggregates, impurities and particulates

The presence of aggregates and similar product-related impurities, as well as process-related impurities such as free DNA accompanying a gene vector, is inferred from differences in molar mass, size or spectral response relative to the desired product. Hence RT-MALS can monitor physical degradation such as aggregate formation or capsid dissociation in the course of a harsh operation such as TFF or viral inactivation. It can also monitor filtration steps to evaluate particulate breakthrough.

RT-MALS is absolute

For most unit operations, RT-MALS provides first-principles measurements that are independent of product-specific calibration curves.

- Basic physical equations connect molar mass with scattered light intensity (measured by MALS) and concentration (measured by UV or dRI). No calibration against product reference standard is needed.

- Similar equations are used to calculate particle size and concentration from the scattered intensity and angular dependence.

- Genomic payload of AAV and other small viral vectors is calculated from light scattering plus UV absorbance at 260 nm and 280 nm.

- The analysis does not depend on molecular shape/conformation or flow rate and is not impacted by multiple scattering.

RT-MALS determines molecular weight from 1000 g/mol to 1 billion g/mol. It can also determine molecular or nanoparticle radius from 10 nm to 250 nm. MALS detectors only require annual calibration.

RT-DLS sharpens the focus

RT-DLS provides first-principles measurements of diffusion coefficients, which are directly related to size and polydispersity.

- Hydrodynamic radius is determined from 0.5 to 500 nm in stop-flow mode and 0.5 – ~ 50 nm in flow mode (upper limit depends on flow rate).

- Polydispersity index provides insight on the particle size distribution.

- DLS requires no calibration, ever.

Not a complete replacement for offline analytics

Offline analytics such as SEC-MALS or batch DLS generally provide comprehensive product characterization, and are worth waiting for. RT-MALS data are not as content-rich, but meet most immediate PAT requirements of process developers and production engineers. Hence RT-MALS can greatly reduce the load on the analytics team while increasing productivity in DSP.

Who uses RT-MALS?

RT-MALS is primarily suitable for monitoring downstream processing (DSP) of biologics as well as the production of synthetic nanoparticles like LNPs.

Bioprocess development scientists working on DSP who normally have to wait days or weeks for fractions or samples to be analyzed in analytical labs, in order to understand the outcome of a new process or modifications to an existing process, gain immediate information on the impact of process parameters, shortening development cycles and reducing time-to-market of a new product.

At the same time, users of RT-MALS gain invaluable process knowledge that can be related directly to scale-up and transferred to process engineers.

Bioprocess engineers who implement RT-MALS can ensure that products are within specifications for each process step, regardless of small changes in process parameters. They will benefit from process knowledge gained in early process development via RT-MALS.

PAT champions immediately recognize the QbD advantages imparted by RT-MALS: direct measurements of relevant product attributes, in real-time, in-line or on-line with unit operations, which will guarantee reliable scale-up, scale-out and site transfer.

Integrate with lab-scale preparative LC – and much more

While integrating an ultraDAWN in-line with preparative liquid chromatography (prep-LC) is perhaps the most straightforward RT-MALS setup, in fact there are multiple ways to make use of RT-MALS, with a variety of process equipment types.

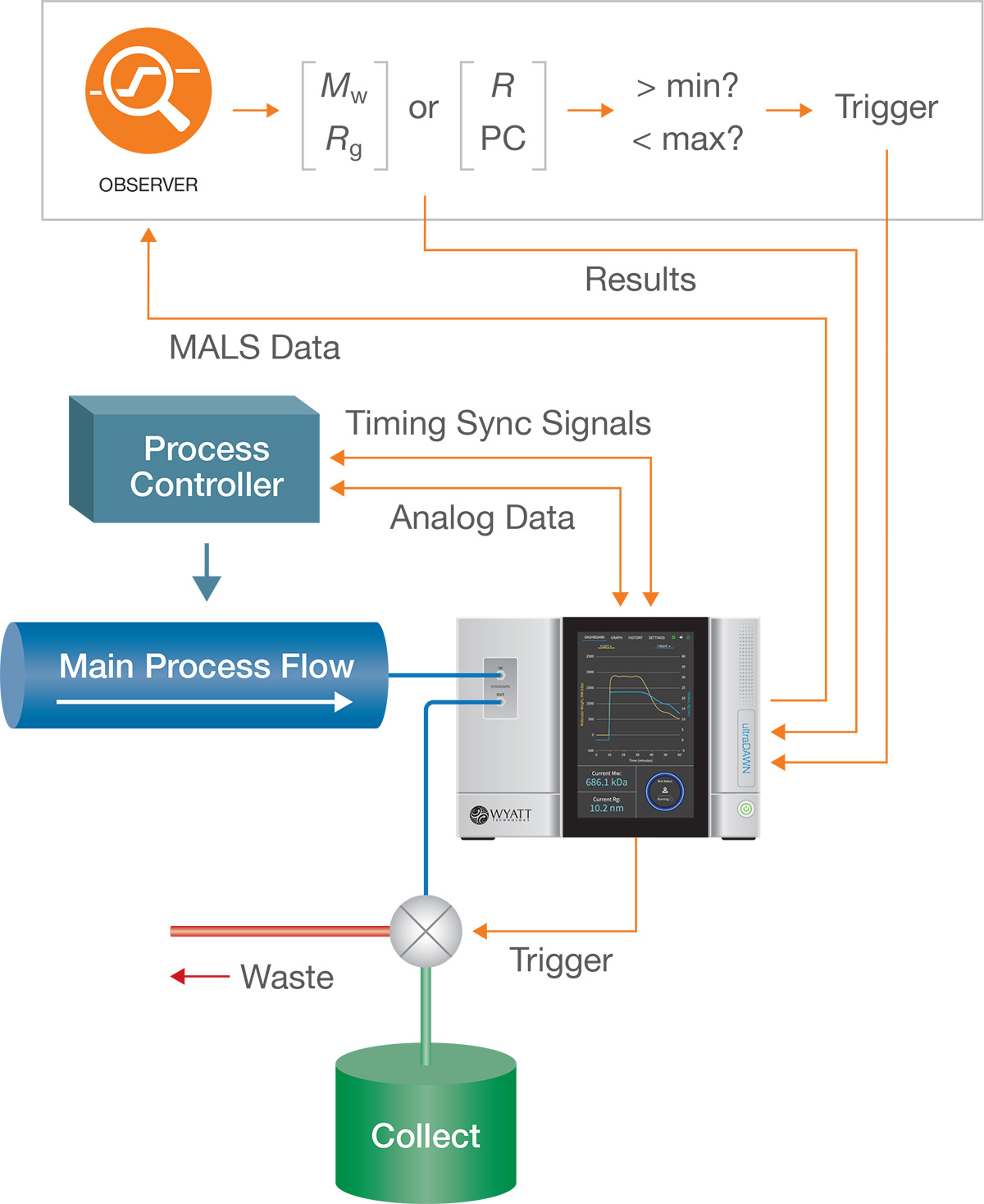

The ultraDAWN is suitable for in-line operation at flow rates from 0.3 to 150 mL/min and beyond, and so is usually plumbed immediately following the column valve or UV detector of a bench-scale prep-LC unit. Various options are available to accommodate higher flow rates. The ultraDAWN/OBSERVER system can exchange analog and digital signals with the prep-LC system to synchronize data collection, transfer analog data between the systems and optimize fraction collection.

RT-MALS operation with other unit operations typically follows one of these configurations: in-line or on-line, described in more detail in the section “What constitutes a complete RT-MALS system?”.

At low flow rates the ultraDAWN is placed directly in-line with prep-LC. For chromatographic operations at high flow rates, one option is to configure the ultraDAWN on-line, using an auxiliary pump to draw a slipstream.

How does MALS work?

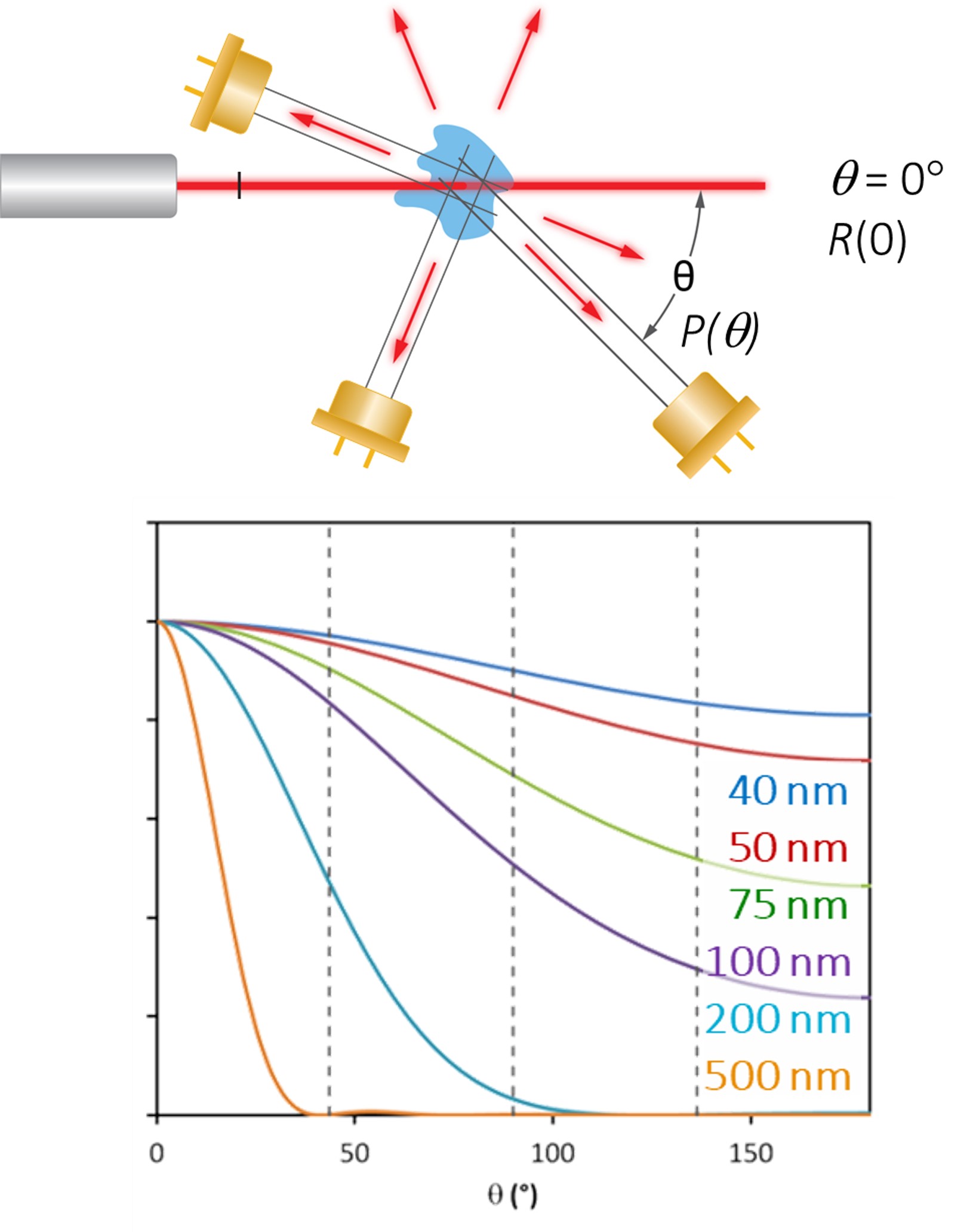

The MALS detector incorporates 18 photodiodes positioned at different angles θ relative to the laser beam to measure the scattered light function R(θ), and one more that measures transmission through the flow cell. At each data point, typically twice or more per second:

- The plot of scattered intensity vs. angle, R(θ), is fit to determine R(0) (the y-intersect at angle θ = 0).

- For macromolecules:

- The weight-average molar mass, Mw, is calculated from the ratio of R(0) and the concentration. Concentration is either derived from UV/Vis absorption, conveyed via analog output to the ultraDAWN, or entered into OBSERVER by the user when concentration is known and constant over the process.

- The z-average radius of gyration, Rg, is calculated by fitting an appropriate equation to the angular dependence of R(θ).

- For nanoparticles including larger gene vectors:

- The z-average radius R is calculated from the angular dependence of R(θ).

- The particle concentration (e.g. viral particles/mL) is calculated from R(0) and the particle radius.

- For AAV and other small viral vectors:

- R(0) is combined with UV absorbance at 260 and 280 nm to determine the molar masses of the proteinaceous capsid and the nucleic acid genome.

- These molar masses are analyzed to determine the full:total capsid ratio Vg/Cp. UV absorbances and molar masses are combined to calculate the total, full and empty capsid titers.

- The rms radius Rg is calculated from the angular dependence of R(θ).

Most of the constants used to determine Mw, radius, particle concentration, Vg/Cp, etc. are related to system optical properties such as laser wavelength and solvent (mobile phase) refractive index. In addition, the analyte’s refractive index (for particles) or dn/dc value, the specific refractive index increment (for macromolecules) in the mobile phase must be known or measured (this is easier than it sounds!) and when using a UV detector the extinction coefficients must be provided. For more details on the theory of MALS, please see our MALS Theory page.

Multi-angle light scattering analyzes the amount of light scattered by the analyte into detectors positioned at various angles relative to the illuminating beam. The extrapolation to zero angle gives molar mass and the angular variation provides the size.

When RT-MALS is insufficient

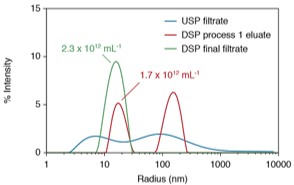

RT-MALS can only determine average molar masses, particle sizes, particle concentrations and Vg/Cp. Particle size distributions as well as concentrations can be measured at-line with a DynaPro™ NanoStar™ or DynaPro Plate Reader dynamic light scattering instrument. Another at-line approach is to combine a microDAWN™ MALS detector for UHPLC with a sampling front end and UHP-SEC separation, providing detailed quantitation every 3 – 5 minutes.

In-process AAV quantitation using a DynaPro Plate Reader for dynamic light scattering analysis of size distributions and virion concentration.

How does DLS work?

The DLS detector, installed at one of four angular positions relative to the laser beam, operates as a very fast single-photon counter. It measures the microsecond-scale fluctuations in scattered light intensity that arise from Brownian motion of the particles, and calculates the autocorrelation function G(τ) every 1 – 10 seconds. At each data slice:

- The autocorrelation function undergoes a cumulants fit to determine the average diffusion coefficient and polydispersity index.

- The diffusion coefficient is converted to hydrodynamic radius via the Stokes-Einstein equation (see DLS theory page). The conversion requires knowledge of the solvent viscosity, entered into OBSERVER via the Solvent Type parameter.

DLS is quite sensitive to flow rate and flow cell type, and there is a tradeoff between the maximum particle size that is measured accurately and the flow rate.

- An ultraDAWN equipped with a standard flow cell will make accurate size measurements up to Rh ~ 50 nm at a flow rate of 0.3 mL/min; higher flow rates or particle sizes lead to increasing deviation from the correct size measurement.

- An ultraDAWN equipped with a special flow cell can extend the flow rate-size tradeoff to Rh = 300 nm at 0.3 mL/min, or smaller sizes at higher flow rates.

- Measurements without flow provide the maximum size range, 0.5 – 1000 nm

OBSERVER 2.0 and higher enable RT-DLS in the online configuration, where OBSERVER controls the pump that draws sample from the process. Thus the flow rate through the ultraDAWN is independent of process flow and can be set to a low value such as 0.3 or 1 mL/min for continuous DLS and MALS measurements with a limited size range.

Alternatively, the pump can be operated periodically. In this mode, MALS data are acquired while sample is flowing and DLS data are acquired while the flow is stopped, enabling the maximum DLS range, accuracy and sensitivity.

What constitutes a complete RT-MALS system?

In-line with FPLC, non-GMP

For RT-MALS in-line with FPLC, all you need are a standard preparative FPLC system with an I/O box for analog input/output and digital signals; ultraDAWN; and OBSERVER for real-time analysis with feedback to the FPLC. Typically this combination will function well for flows up to 150 mL/min and may be extended to ~ 2 L/min by implementing a flow splitter that partially bypasses the ultraDAWN inlet, with the two streams recombining at the ultraDAWN outlet.

When monitoring proteins, nucleic acids or AAVs, the FPLC UV detector signal(s) are conveyed via analog cables to the ultraDAWN. Measurements of proteins or nucleic acids require one UV wavelength, while AAVs require two (260 nm and 280 nm). UV is not needed for monitoring larger viral vectors, though the signals may be read into OBSERVER for comparison and synchronization purposes.

Data collection between the FPLC software and OBSERVER is synchronized via exchange of digital pulses. In addition, OBSERVER can output two types of analog signals to the FPLC:

- Trigger: A +2 V ‘trigger’ signal used to indicate that the eluting material meets the pooling criteria;

- Data: An analog voltage proportional to one of the measured properties (e.g. molar mass or Vg/Cp) which may be read into the FPLC software, displayed and stored with the native data and used for fraction collection logic.

ultraDAWN works with popular FPLC systems in protein, nucleic acid, viral vector, phage and exosome purification labs.

In-line with other systems, non-GMP

ultraDAWN can be operated in-line with other systems providing relatively low flow, e.g. a bench-scale microfluidic nanoparticle production setup. The limit for in-line operation is usually the backpressure on the process equipment: ultraDAWN produces 0.7 bar (9 psi) at 150 mL/min. A flow splitter may be implemented for higher flow rates up to ~ 2 L/min.

Most other systems with relatively low flow rates will not have the full-featured control software that FPLC offers. Data collection and process synchronization will usually be controlled manually via OBSERVER. However, if the user provides appropriate analog-to-digital capabilities, similar integration can be performed as with FPLC.

On-line with chromatography, non-GMP

For at-scale process chromatography, the flow rate may be too high to fully go through the ultraDAWN, even with a flow splitter. The main limitation is backpressure on the column due to the ultraDAWN. In this case:

- an auxiliary pump such as: a peristaltic or similar pump draws off a small, continuous slipstream from the main process flow, at 0.1 – 50 mL/min. This is suitable for any process scale.

On-line with other process equipment, non-GMP

Using the auxiliary pump, ultraDAWN can also be connected to UF/DF, fill-finish equipment-, and microfluidizers or homogenizers, as well as stationary vessels like chemical reactors. Drawing from a reservoir such as the UF/DF retentate or microfluidizer sample reservoir is preferable to drawing from the process tubing. An auxiliary pump may also be set up to draw solution from a high-flow-rate process such as an LNP-RNA mixing system.

Usually these do not offer analog-digital interfaces, but if they are available, ultraDAWN can take advantage of them, for example using the analog trigger output to control quenching a reaction or switching a valve between pool and waste. If UV measurements are needed they can be provided with a stand-alone UV detector placed between the pump and ultraDAWN.

A pump can optionally be configured to perform continuous dilution of the sample. Dilution is important for these specific conditions:

- When the solvent has very low ionic strength, light scattering measurements may not be feasible. The sample is diluted with moderate- or high-ionic-strength buffer in order to screen electrostatic interactions between molecules and enable good light scattering data.

- When the mobile phase has varying ionic strength and high eluting concentration (> 5 mg/mL), the sample is diluted in order to achieve a nearly constant, well-buffered condition and weak intermolecular interactions.

- When the sample is extremely turbid, it is diluted in order to enable light transmission.

OBSERVER supports the Waters Arc™ Premier BSM-R binary pump for purposes of continuously or periodically drawing and diluting sample to the ultraDAWN. It is best used in the context of an unpressurized vessel or reservoir at atmospheric pressure. For flowing systems, this is only feasible if the sampling point pressure is < 1 psi.

GMP compatibility

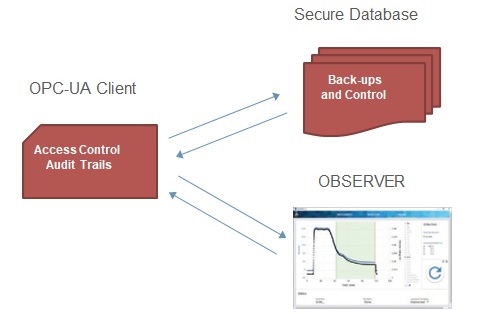

Software:

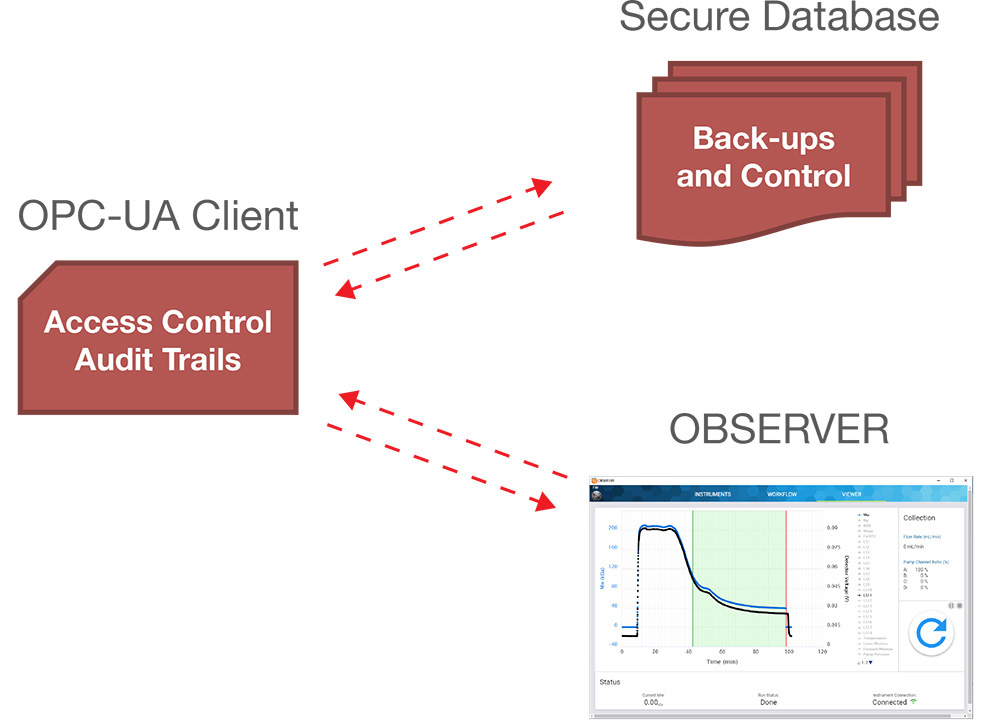

- OBSERVER is available with OPC-UA connectivity. Users may write an OPC-UA client that takes care of compliance requirements such as a secure database or audit trails, automated or remote control, and transfer of data to a historian or PAT monitoring system. The OBSERVER UI is locked against user intervention when connected to an OPC-UA client.

Hardware:

- The ultraDAWN is compliant with IP42. It may be housed in a cabinet for IP55 compliance.

- For clean-in-place, the flow path may be sterilized with 1 M NaOH, 10% HNO3, 70% IPA or most other standard sterilization solutions. Wyatt does not currently offer a cleaning validation protocol.

- A single-use flow path is not offered at this time.

- At this time, the recommended paths to GMP implementation are inline with CIP or online with sample discard. Please contact Wyatt Technology for a comprehensive review of GMP requirements and capabilities.

For chromatographic operations at high flow rates, ultraDAWN is configured on-line using an HPLC pump to draw a slipstream. At lower flow rates the ultraDAWN is placed directly in-line with the FPLC.

Quantify product attributes when and where it counts most

The key application areas of RT-MALS are biotherapeutics, vaccines, viral and non-viral gene vectors and nanoparticle drug delivery vehicles. Below you will find a select set of applications. Additional links to application notes, webinars, our searchable bibliography and more are available in the Resources tab.

If you find something promising, please contact us by clicking on the Request Info button, and an expert Application Scientist will be in touch to help ascertain if RT-MALS meets your specific PAT goals.

Vaccines

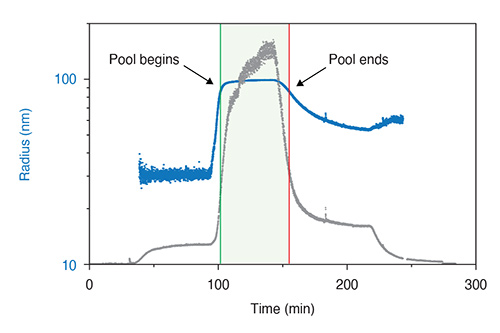

In order to collect virus-enriched fractions during ion-exchange chromatographic purification, RT-MALS monitors particle radius R. The trigger is set to turn on and activate a collection valve when R is within a suitable range for differentiating monomeric virus particles from smaller proteins, DNA, virus aggregates or cell lysate fragments. At the same time, it calculates viral particle concentration for immediate determination of titer in the pool.

Learn how MALS is used in rapid at-line monitoring of virus-like particle purification in Aguilar et al., “At-line multi-angle light scattering detector for faster process development in enveloped virus-like particle purification”, J. Sep. Sci. (2019)

RT-MALS optimizes chromatographic purification of viral vectors by discriminating viruses from impurities.

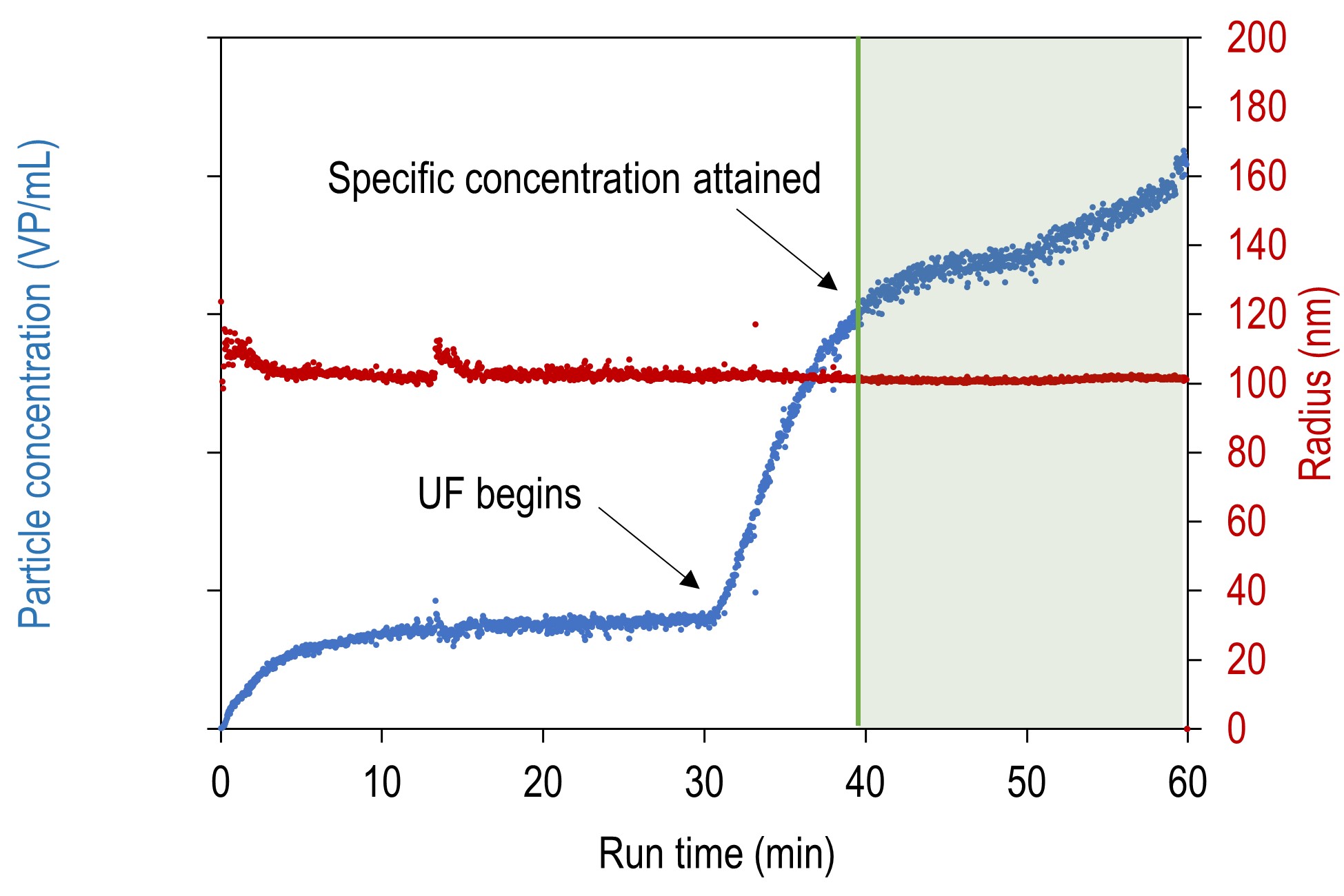

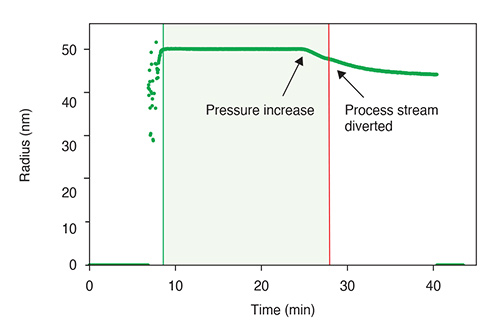

Ultrafiltration

A tangential flow filtration step for concentrating viral vectors can be controlled by an ultraDAWN set up to monitor particle concentration. The ultraDAWN is connected to the TFF flow path in an on-line configuration by a pump and continuously receives sample (which is subsequently returned to the TFF system). In OBSERVER, the trigger is programmed to turn on when the concentration is above the specified end point, signaling to the control system to terminate the process.

Simultaneously, the viral size is monitored to immediately identify potential particle degradation.

View recent webinars on the use of RT-MALS for monitoring downstream viral vector production processes.

UF/DF of viral vectors is both controlled and monitored for product quality by ultraDAWN with OBSERVER real-time software.

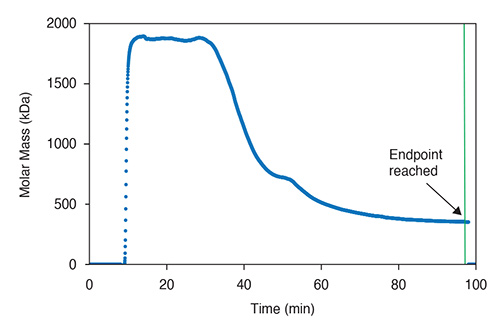

Polysaccharide depolymerization

In this process, hydrolysis of the polysaccharide must be quenched when it reaches the target molecular weight of 350 kDa. Using the on-line configuration, sample is continuously drawn from the reactor, diluted with buffer and delivered to the ultraDAWN. RT-MALS monitors molecular weight and sets the trigger when MW is below the specified end point.

Download the application note AN8005: RT-MALS end-point determination of a polysaccharide depolymerization process. MALS has also been demonstrated in-line with preparative size-exclusion chromatography for real-time monitoring of protein-polysaccharide conjugate purification in Rajendar et al., “Multi angle light scattering as a process analytical technology tool for real-time monitoring of molar mass of protein-polysaccharide conjugate fractions”, J. Chromat. Open (2022).

RT-MALS ensures product quality in this depolymerization step, regardless of variations in the starting material.

Biotherapeutics

Protein purification

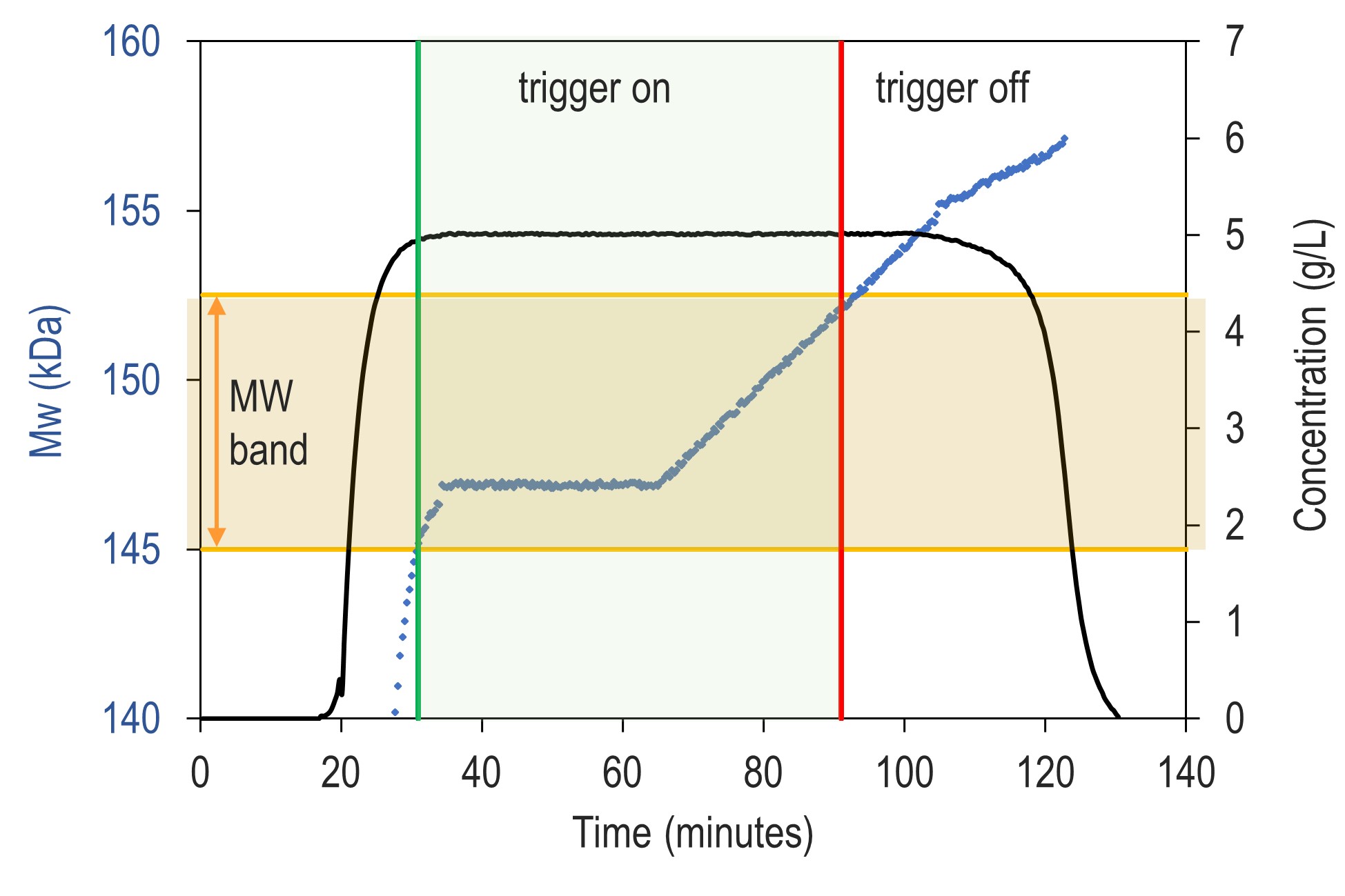

The weight-average molecular weight determined by RT-MALS can be used to estimate aggregate content in a polishing step using an ultraDAWN in-line with flow-through hydrophobic interaction chromatography. In this example with a 146.8 kDa mAb, OBSERVER’s trigger is programmed for a band between 145 and 152.5 kDa, the latter corresponding to 3.5% aggregate. The trigger turns on at 31 minutes and off at 91 minutes for overall aggregate content in the pool of 0.9%.

Read how RT-MALS was first demonstrated to provide highly accurate monitoring of aggregate load during flow-through mAb purification in Patel et al., “Multi-angle light scattering as a process analytical technology measuring real-time molecular weight for downstream process control”, mAbs 2018.

An example of in-line MALS for monitoring and optimizing the pooling of a monoclonal antibody Fab arm purified by bind-and-elute ion-exchange chromatography appears in AN8004: Coupling MALS with preparative ion-exchange (pIEX) for structural biology applications.

Real-time molecular weight monitoring identifies aggregate content in order to optimize yield while maintaining overall pool quality.

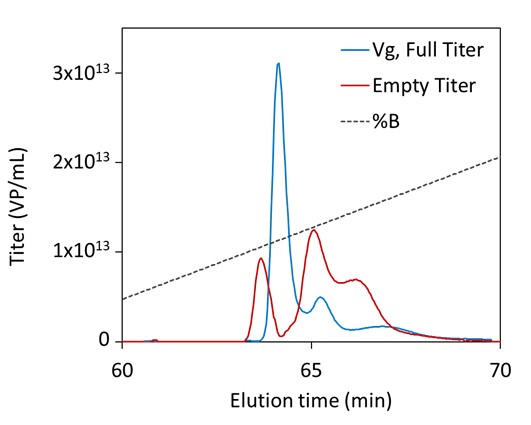

AAV enrichment

Ion-exchange chromatography (IEX) is a common method for separating empty and full adeno-associated viral vectors as well as removing residual impurities. RT-MALS may be implemented in prep-scale IEX systems in order to monitor the capsid particle and viral genome concentrations of every eluting fraction, and signal when Vg/Cp is above a specified value in order to control pooling. At the same time ultraDAWN and OBSERVER provide other key product attributes that can be related to aggregation and discrimination between AAVs and process impurities like free DNA.

Learn how RT-MALS is used to accelerate the development of a process for AAV enrichment by ion-exchange chromatography in our application note AN8008: Real-time monitoring and control of AAV chromatographic enrichment with RT-MALS.

Both capsid particle and viral genome concentrations are monitored by RT-MALS, along with the capsid ratio Vg/Cp, capsid and genome molar masses and virus size. Together these indicate pooling for enrichment while eliminating aggregates and impurities.

Nanoparticle drug delivery

Liposome homogenization

Incoming liposomes begin with a wide size range but are reduced to a uniform size via homogenization, emerging within a narrow size band. RT-MALS monitors product attributes such as radius and concentration; if they fall outside the specified range, OBSERVER signals the process control system to divert out-of-spec product to waste in order to avoid contaminating the collection vessel.

Download the application note AN8006: In-line monitoring of liposome size by RT-MALS.

ultraDAWN monitors nanoparticle production processes such as extrusion, homogenization of microfluidic precipitation in order to flag deviations from specified product attributes.

Shed new light on your process

No more long waits for offline sample analyses. No more wasted batches. With RT-MALS you can finally see what you need to know – true product attributes – in your PD lab or on the production floor, in real time, measured directly, no models.

How do I use RT-MALS?

Since RT-MALS is used with a variety of processing steps and equipment, the specifics of how it is used will depend on the application. A general outline is:

- Get the sample to the ultraDAWN.

- If the ultraDAWN is in-line with the process flow, this is trivial.

- If the on-line configuration is used, connect inlet line A of the auxiliary pump to the sample source (reactor vessel or main process flow line). Inlet line B is placed in a bottle with the process buffer.

- For monitoring macromolecules or AAVs, set up the concentration source.

- A reactor vessel might have a constant concentration

- Other systems will require a UV analog signal or other detection method, and the delay volume between the concentration detector and ultraDAWN must be established.

- AAV monitoring requires two UV wavelengths

- Acquire baseline values

- In-line configuration: run elution buffer or whatever solvent will be present with the product.

- On-line configuration: The process buffer/solvent is provided from inlet line B.

- Begin the process – OBSERVER calculates, displays and exports product attributes

- If using OBSERVER’s trigger functionality: Begin testing for trigger conditions in OBSERVER. When they are met, the trigger signal will go high, indicating whether to end the process, switch a valve or begin collecting fractions. Under certain trigger logic specifications the trigger will go low when conditions are no longer met, and then high again if they return.

- Alternatively, the process software can use the attribute values to make its own decisions regarding operations, or the values can simply be recorded for later review.

ultraDAWN is generally calibrated once or twice per year and does not require calibration curves for most products. If a new solvent is introduced that differs significantly in refractive index from the previous solvent, it may be necessary to perform ‘normalization’, a simple procedure that involves flowing through the ultraDAWN 40 KDa dextran or a similarly small polymer or protein dissolved in the new solvent.

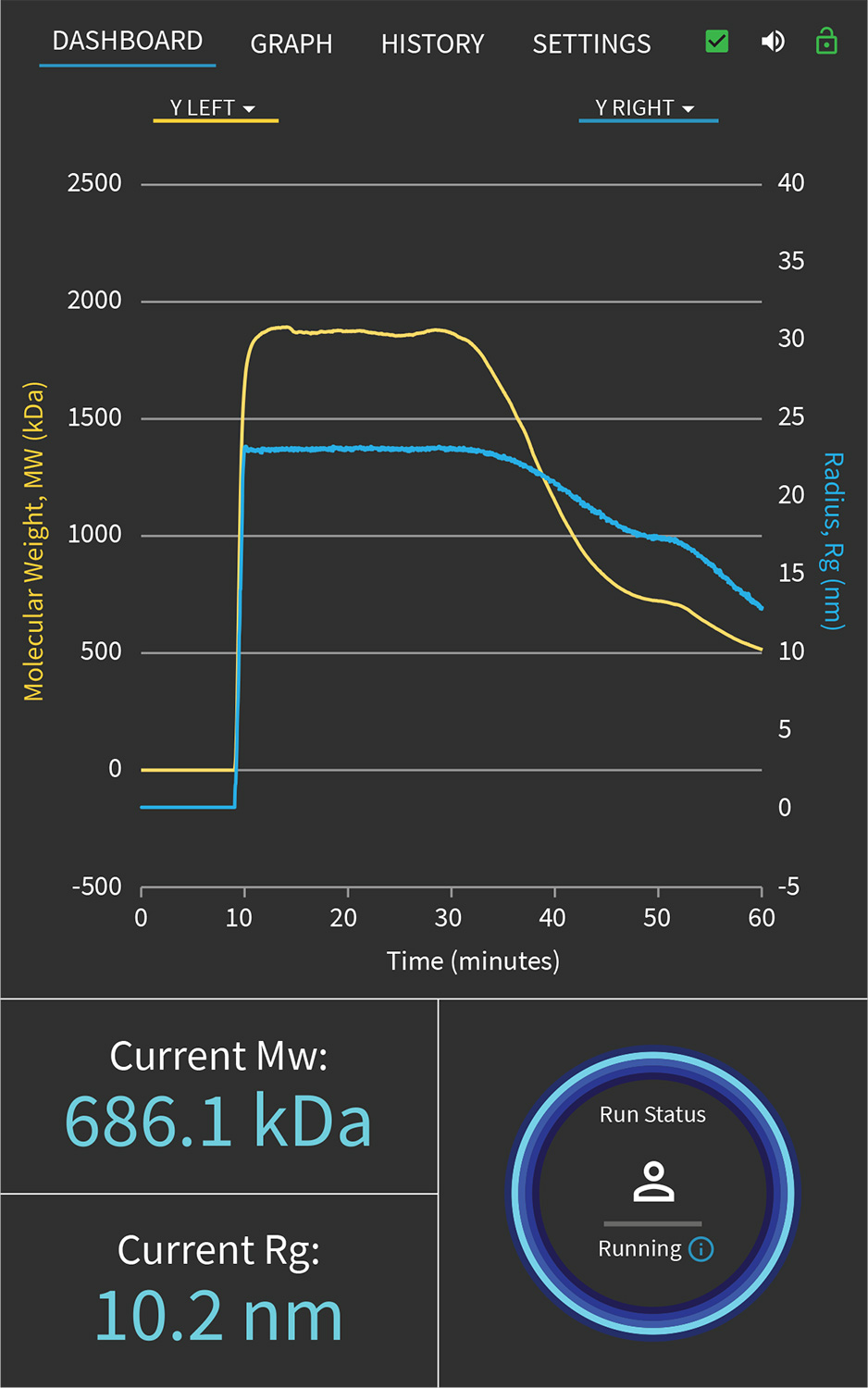

When connected to OBSERVER, the ultraDAWN’s touch-screen display provides real-time readings of current and recent measured attributes.

OBSERVER workflows

Operation of OBSERVER is based on customizable workflows:

- Inline or Online Macromolecule – for monitoring and controlling processing of polysaccharides, proteins, etc.

- Inline or Online Nanoparticle – for monitoring and controlling processing of viruses, LNPs, liposomes, etc.

- Inline AAV – for monitoring processing of AAV, other small viral vectors or virus-like particles encapsidating nucleic acids, or small UV/Vis-active nanoparticles (up to ~ 50 nm in diameter) that encapsulate drug substances like peptide or small-molecule drugs.

- Performance Qualification

- Automated cleaning

In-line Macromolecule, Nanoparticle or AAV

OBSERVER’s in-line workflows:

- Synchronize with an FPLC or microfluidic system

- Report for the main process flow

- Macromolecules: weight-average molar mass Mw and z-average rms radius Rg

- Nanoparticles: z-average rms radius R and particle concentration PC

- AAV: total, full and empty particle concentration; total, capsid and payload molar mass; full-total ratio; z-average rms radius Rg

- Report for the collected fraction

- Macromolecules: Mw and total mass

- Nanoparticles: PC and total number of particles

- AAV: total, full and empty particle concentration; total, capsid and payload molar mass; full-total ratio; z-average rms radius Rg, and total number of capsids, number of full capsids and number of empty capsids.

On-line Macromolecule or On-line Nanoparticle

OBSERVER’s on-line workflows:

- Control an auxiliary pump to:

- Draw a sample flow from the main process flow

- Dilute the sample up to 10:1

- Pass the sampled product to the ultraDAWN

- Report for the main process flow

- Macromolecules: Mw and Rg

- Nanoparticles: R and PC

OPC-UA operation

Basic OBSERVER operation is controlled and data are reviewed from a Windows graphical user interface. For GMP operation, OBSERVER becomes an OPC-UA server. A user-supplied client program communicates with OBSERVER to perform control and data retrieval.

21 CFR Part 11 compliance for RT-MALS is achieved via OPC-UA control.

ASTRA

ASTRA software is used when real-time measurements are not needed and it is sufficient to acquire the data during the process, then analyze afterwards. ASTRA is built in many ways like typical chromatography software.

For those in GMP/GLP-regulated environments, ASTRA’s Security Pack add-on enables 21 CFR Part 11 compliance including full audit trails and electronic signatures.

Wyatt Technology provides several avenues for supporting novice and advanced users, including tutorials, training materials and technical notes in the online Wyatt Support Center; phone and email support; and Light Scattering University. Site visits may be arranged for IQ/OQ, service and preventive maintenance as well as group training.

With ultraDAWN, ASTRA provides comprehensive characterization methods for post-process analytics.

Based on Wyatt’s award-winning MALS technology

More than 45 years ago, Wyatt Technology's scientists invented the very first commercial light scattering instruments incorporating lasers as their light source. We've been defining and redefining the state-of-the-art for laser light scattering hardware, software, training and services to meet customer needs for over three and a half decades.

With RT-MALS, Wyatt brings that same commitment to PAT for process development scientists and production engineers.

Founded in 1982 by Dr. Philip Wyatt (center), Wyatt Technology still maintains its core values of quality and personal service.

MALS

ultraDAWN

ultraDAWN - The only MALS detector for process and real-time operation. Incorporates detectors at 18 angles to determine molar masses from 1000 Da to 1 GDa and radii from 10 to 250 nm, as well as a transmission detector for obtaining accurate scattering measurements under turbid conditions.

- Standard option: ambient temperature; accommodates flow rates from 0.3 to 150 mL/min with tubing changes, and up to 2 L/min with a passive flow splitter

- Heated/cooled option: -15° C to +150 °C; accommodates flow rates from 0.3 to 5 mL/min

Both ultraDAWN versions accept WyattQELS embedded DLS modules and optical attenuators in order to measure turbid solutions. Learn more.

Software

OBSERVER Real-time MALS measurements for process analytics and process control.

- Accepts MALS data and UV analog data (digitized by the ultraDAWN) to quantify product attributes of macromolecules, nanoparticles and AAVs or other sub-50 nm vehicles for gene or drug delivery.

- In-line: integrates with FPLC and similar systems via analog and digital signal exchange. Outputs analog trigger signal and analog data to FPLC system.

- On-line: controls an auxiliary pump to draw a slipstream with optional dilution. Outputs analog trigger signal to process control.

- Macromolecules: determines molar mass and rms radius. Aggregate level can be estimated from changes in molar mass.

- Nanoparticles: determines average particle size and concentration. Particles are discriminated from free macromolecules by size.

- AAVs (and other small vectors): determines Vg/Cp, total and full concentrations, capsid and payload molar mass, rms radius. Aggregate levels can be estimated from changes in capsid molar mass.

- OPC-UA connectivity for commercial processes and GMP operation

ASTRA - Comprehensive post-process analysis of in-MALS measurements to determine molar mass, size, particle concentration and more. Also analyzes online DLS data.

- The Security Pack add-on enables 21CFR(11) compliance, including full audit trails and electronic signatures.

Explore RT-MALS

Delve deeper to learn how RT-MALS works and performs real-time quantification of product attributes for proteins, viral vectors, lipid nanoparticles and more. These resources are all available on our web site.

Webinars

On-demand webinars presenting the theory and applications of RT-MALS are available for unrestricted viewing on the RT-MALS Webinars page. Listed below are some of the most popular:

Application notes and white papers

Application notes and white papers highlighting the use of RT-MALS are available for unrestricted viewing on the RT-MALS Application Notes page. Listed below are some of the most popular:

Theory

Please see the following pages for details of MALS theory:

These pages provide additional information on specific analyses performed in RT-MALS:

Bibliography

An extensive searchable bibliography of publications Wyatt SEC-MALS instruments is available at www.wyatt.com/Bibliography. Just open the Advanced Search and click the Multi-Angle Light Scattering box, then enter your search terms below.

Technical Notes

Wyatt offers its customers comprehensive online support via the Wyatt Support Center, including many technical notes that can help make the most of RT-MALS experiments. If you are a customer and do not have access, please request an account on the Support Log-in page.

At Wyatt, it’s personal

Your success is ours! From the time you purchase a Wyatt instrument, we are there for you every step of the way and give you more than just an instrument warranty. Wyatt provides a full suite of support offerings to help you make the most of your investment. Most importantly, you get unrivaled personal attention to ensure success and productivity.

On-site installation and training

With every instrument purchase, we offer an on-site installation and familiarization visit at your laboratory to ensure proper instrument set-up and function. We also offer customized on-site training tailored to your specific needs. These additional services may be especially desirable if a large group of staff members wants to receive instruction.

First-year service and support

All new Wyatt instruments come with a full year of unlimited telephone and e-mail support as well as our standard full-coverage warranty during the first year. Our congenial staff of Ph.D. scientists and expert technicians provides both technical and application assistance. We will show you how to analyze your data or set up instrument communications by remotely accessing your PC.

After the first year, annual service plans are available for continuing, unlimited telephone support, e-mail support and instrument service. Benefits of the service plans include annual preventive maintenance, on-site calibration, re-qualification, and discounts on parts and labor for repairs. Learn more about service plans.

The specifics of first-year service as well as continuing support may vary by region. Please contact your local Wyatt representative for more information.

IQ/OQ and compliance

Wyatt Technology offers a complete compliance program including documentation and on-site validation for all of its instruments. We provide the resources and tools necessary to ensure compliance. We’ve worked extensively with our partners in compliant environments to build up a robust set of documents and services. Wyatt instruments and software are used in GMP environments at pharmaceutical, biotech, and other regulated industries around the world. Learn more about our Compliance program.

Light Scattering University

Our flagship training program Light Scattering University® (LSU) is included with every purchase of a light scattering instrument. In the 2, 3 or 4 day course—depending on which system is purchased—LSU students discover advanced data processing methods and alternative analytical tools they may not be familiar with. The students also learn how their MALS and DLS data complements information from other techniques they are using in the lab. Advanced classes are offered for LSU graduates on more detailed techniques and topics.

During LSU our students meet Dr. Philip Wyatt, Founder and Chairman of the Board who gives an acclaimed Light Scattering Instrument Museum tour. Students also meet those who invent, build, service and support the instruments, so they know the team that will support them when back in the lab.

An LSU credit, inclusive of airfare, accommodations and most meals, is included for North American customers who purchase one of our light scattering instruments. While you are here, we work you hard but feed you well—at a variety of Santa Barbara restaurants!

Learn more here.

Service and Support Plans

At Wyatt, we understand that downtime and loss of productivity is critical and have developed comprehensive service offerings — our Platinum, Gold and Silver Service Plans — specifically designed to make preventative maintenance and instrument repair requests quick, smooth and hassle-free. These plans are available on an annual basis after the first-year instrument warranty expires and offer priority phone and e-mail support in addition to instrument service.

The Platinum and Gold Service Plans offer comprehensive on-site preventive maintenance, repair services and software updates. A highly trained Wyatt Field Service Engineer will come to your facility and perform annual or semi-annual preventative maintenance, calibration and optional re-qualification checks. We also offer loaner units should an instrument require factory repair. With our Silver Service Plan, you can expect full instrument calibration and quality control testing, priority service including parts, labor, shipping, as well as the same comprehensive, first-priority technical and application support by phone, email, and screen sharing sessions as offered with the Platinum and Gold Service Plans.

Learn more here.

![]()

Web-based support

Our Customer Support Center contains a wealth of useful resources on everything related to your Wyatt light scattering instruments, software and applications:

- Software updates and bug fixes

- Technical Notes on how to connect and work with your instruments and software

- Video tutorials, software tutorials and educational webinars

- Learning Resource section with New User Guides

- Reference materials such as User's Manuals, Certificates of Analysis for Wyatt-supplied standards, CE and TUV declarations

Register or log in to the Support Center here.

We're Here to Help

Phone number +1 805-681-9009 option 4

Business hours: M-F 8 a.m. - 5 p.m. Pacific

Consulting

By special arrangement, we can provide extended on-site consulting services by an Applications Scientist to set up methods and run samples on your instruments in your lab. This avoids the need to send samples off-site for analysis and allows for intimate, real-time consultations with the best experts available. Availability may be limited to certain geographical regions.

If you would like to have our lab staff analyze samples for you and provide consultations, explore Wyatt's in-house Sample Analysis services.

Wyatt Technology Store

With our online store, world-wide customers can search for parts, consumables and accessories and view product images and part numbers. The store is categorized by Wyatt product families making it easy to know which parts are compatible with your instrument. US and Canadian customers can register for an account and order parts and accessories with either a purchase order or a credit card.

Browse our most popular consumables, review your order history and easily place repeat orders online. If you have questions on which Waters™ Wyatt protein SEC column is best for your application, check out the friendly SEC Columns Guide which will interactively guide you to the recommended column. In addition to ordering parts and accessories, you can also inquire about our training courses, IQ/OQ validation, and service plans.

Visit our online store here.