ultraDAWN™

Product Overview

Product Description

Brochure

Real-Time Operation

Process Analytical Technology

Applications

Software

Specifications

Other MALS Instruments

Request Info

A breakthrough in process analytical technology for production of nanoparticles, biopharmaceuticals and polymers.

Real-Time Multi-Angle Light Scattering

ultraDAWN measures multi-angle and dynamic light scattering and reports the results – molecular weight, size, polydispersity, particle concentration and more – in real time. With RT-MALS, critical quality attributes (CQAs) can be monitored directly, for rapid feedback on product and process quality.

Benefits of RT-MALS

- Accelerate process development and scale-up

- Increase yield, reduce overall time until lot release

- Maintain product quality with confidence

Where MALS and PAT meet

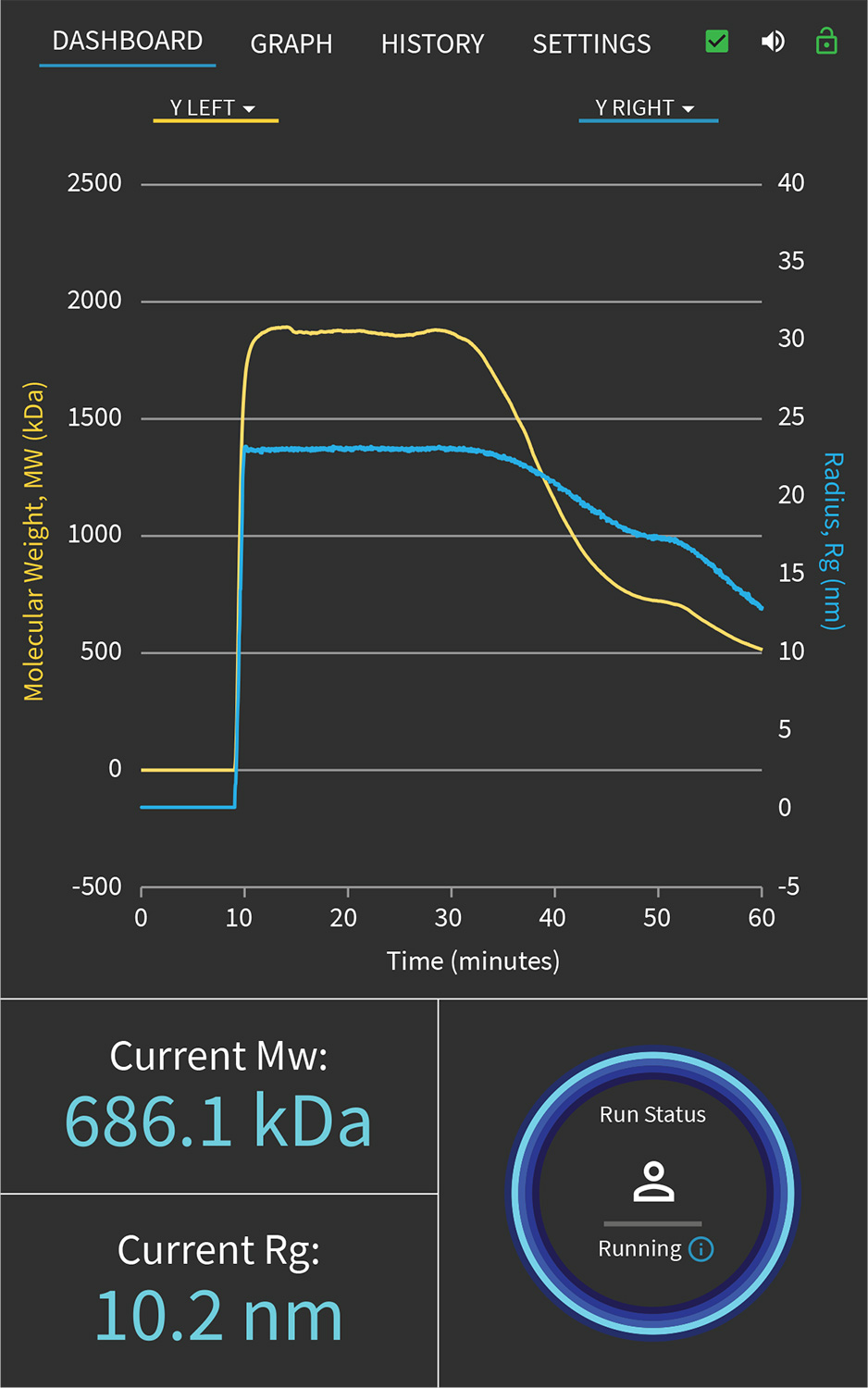

The ultraDAWN is a unique member of the DAWN™ family of MALS instruments. Instead of residing in the analytical lab, it is adapted to bioprocess development and production environments. Together with OBSERVER™ real-time software, ultraDAWN calculates and reports molar mass, size, particle concentration and other attributes, up to 300 times per minute, during a unit operation such as chromatographic purification or lipid nanoparticle production.

PAT instrumentation typically monitors process parameters such as pH, temperature, pressure, UV and feedstock, which are tied only indirectly to product properties and quality. ultraDAWN revolutionizes process development with its continuous, direct measurements of relevant product attributes.

Built in the NEON™ platform, ultraDAWN provides an intelligent user interface indicating real-time and time sequences of molar mass, size and/or particle concentration as well as system health diagnostics and event history. With photodetectors at eighteen scattering angles plus one more to measure light transmitted through the flow cell, the ultraDAWN provides a solution for monitoring multiple biophysical product attributes:

Macromolecules:

- Mw from 103 to 109 g/mol

- Rg from 10 to 250 nm

Nanoparticles:

- radius from 10 to 250 nm

- particle concentration (concentration range depends on particle size)

AAV and other small viral vectors:

- full:total capsid ratio Vg/Cp

- total, full and empty capsid titer (AAV/mL)

- total AAV, capsid and genome molecular weight

- rms radius Rg

With the addition of an optional WyattQELS embedded DLS module, ultraDAWN also monitors hydrodynamic radius from 0.5 to 1000 nm (flow-rate dependent) and the polydispersity index.

ultraDAWN offers versatile options for PAT, including:

- In-line or on-line configuration

- In-line flow up to 150 mL/min, and up to 2 L/min with a flow splitter

- Process sampling or slipstream sampling with recirculation 0.5 to 50 mL/min

- Process sampling with dilution 0.1 to 5 mL/min

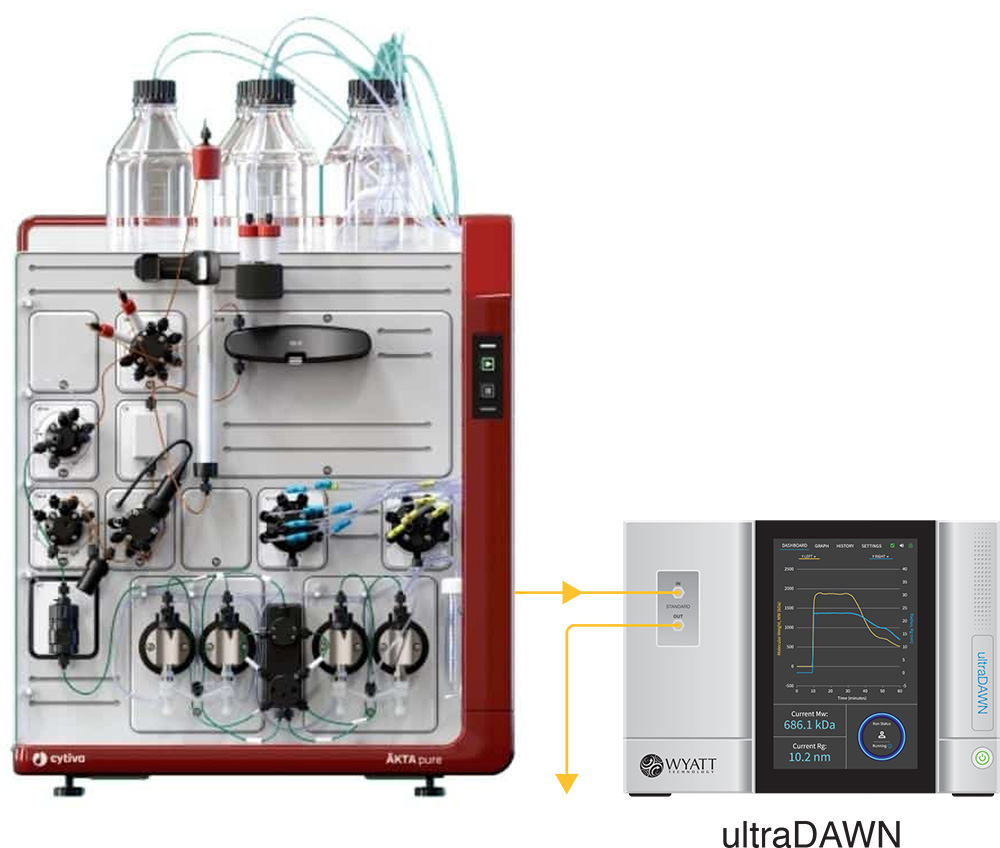

- Analog integration with bench-scale preparative chromatography and other processing equipment

- Digital integration with production control software via OPC-UA

Monitor and control production processes of nanomedicines and biopharmaceuticals

Click here to request a copy of our ultraDAWN brochure.

Process integration options

Process integration options

- In-line or on-line configuration

- In-line flow up to 150 mL/min, extendable to 2 L/min

- Process sampling or slipstream flow rates from 0.1 mL/min to 5 mL/min

- Integration with production control software via OPC-UA

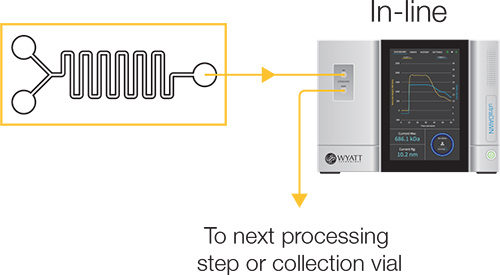

In-line - For continuous processes that take place at flows up to 150 mL/min (up to 2 L/min with a passive flow splitter), such as microfluidic drug encapsulation or chromatographic purification steps, in-line RT-MALS provides the shortest feedback loop while the ultraDAWN samples the entire process stream.

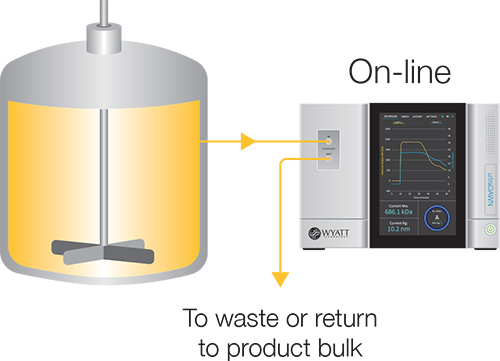

On-line - When processing takes place within a fixed volume such as a homogenizer, or when the process flow is greater than 2 L/min, the solution is sampled or a bypass stream is diverted from the manufacturing process to the ultraDAWN. RT-MALS data are produced in near-real-time.

RT-MALS for PAT

A PAT strategy that incorporates ultraDAWN for RT-MALS sees reduced development time and fewer samples sent to off-line analytical labs. With real-time CQA analysis, process margins can be optimized and attribute drifts detected immediately, reducing discarded product and increasing yield.

RT-MALS in Lab R&D

RT-MALS can be implemented early in process development – at pilot plant scales and even smaller, such as regular production of small batches of material for R&D use. Experience with lab-scale RT-MALS paves the way for effective implementation on the production floor.

RT-MALS in Scale-up from Lab to Manufacturing

Scaling up often means re-developing the process, requiring off-line analysis of numerous samples collected from intermediate and final steps. RT-MALS greatly accelerates scale-up: it provides real-time feedback, indicating the effect of method tweaks on CQAs, while simultaneously reducing effort and the number of samples analyzed off-line.

Unlike complex at-line PAT devices, ultraDAWN can simply be left in the process flow upon completion of scale up, for continuous or periodic monitoring of the final process.

RT-MALS on the Manufacturing Floor

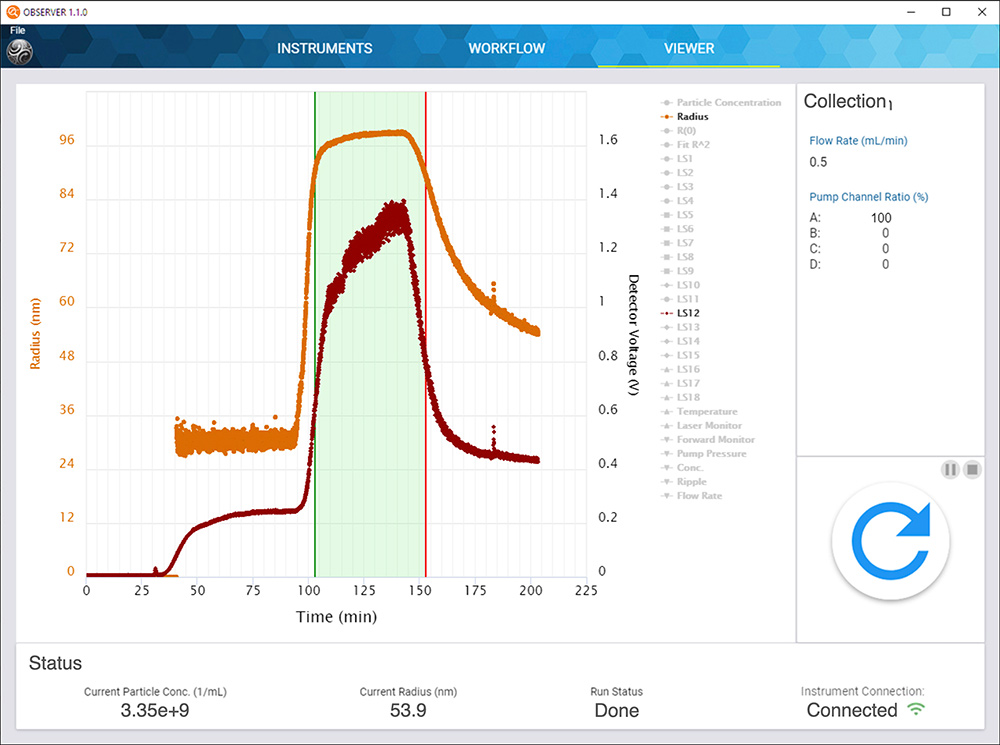

ultraDAWN and OBSERVER™ software are simple, robust technologies that may be employed in different ways during serial production. During initial stages, technicians can visually monitor molar mass and size, intervening in the process as needed. With increasing confidence in the capabilities and reliability of RT-MALS, engineers may implement fully-automated process control using OBSERVER’s configurable triggers. In both cases, all data can be reviewed post-production to determine if any deviations were encountered.

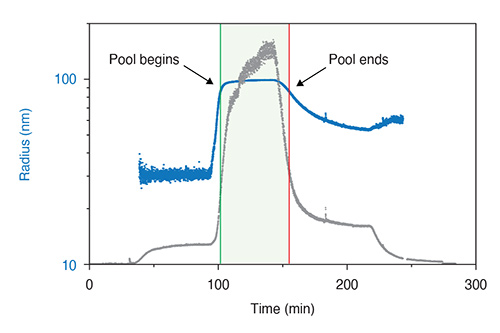

Virus purification

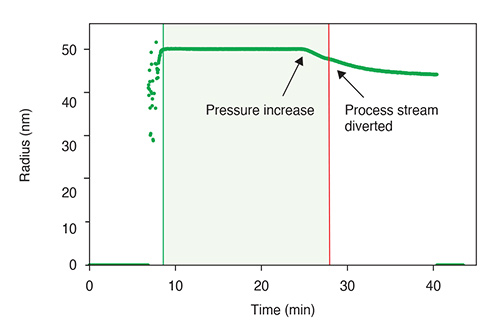

In order to collect virus-enriched fractions during ion-exchange chromatographic purification, RT-MALS monitors particle radius R. The trigger is set to turn on and activate a collection valve when R is within a suitable range for differentiating monomeric virus particles from smaller proteins, DNA, virus aggregates or cell lysate fragments.

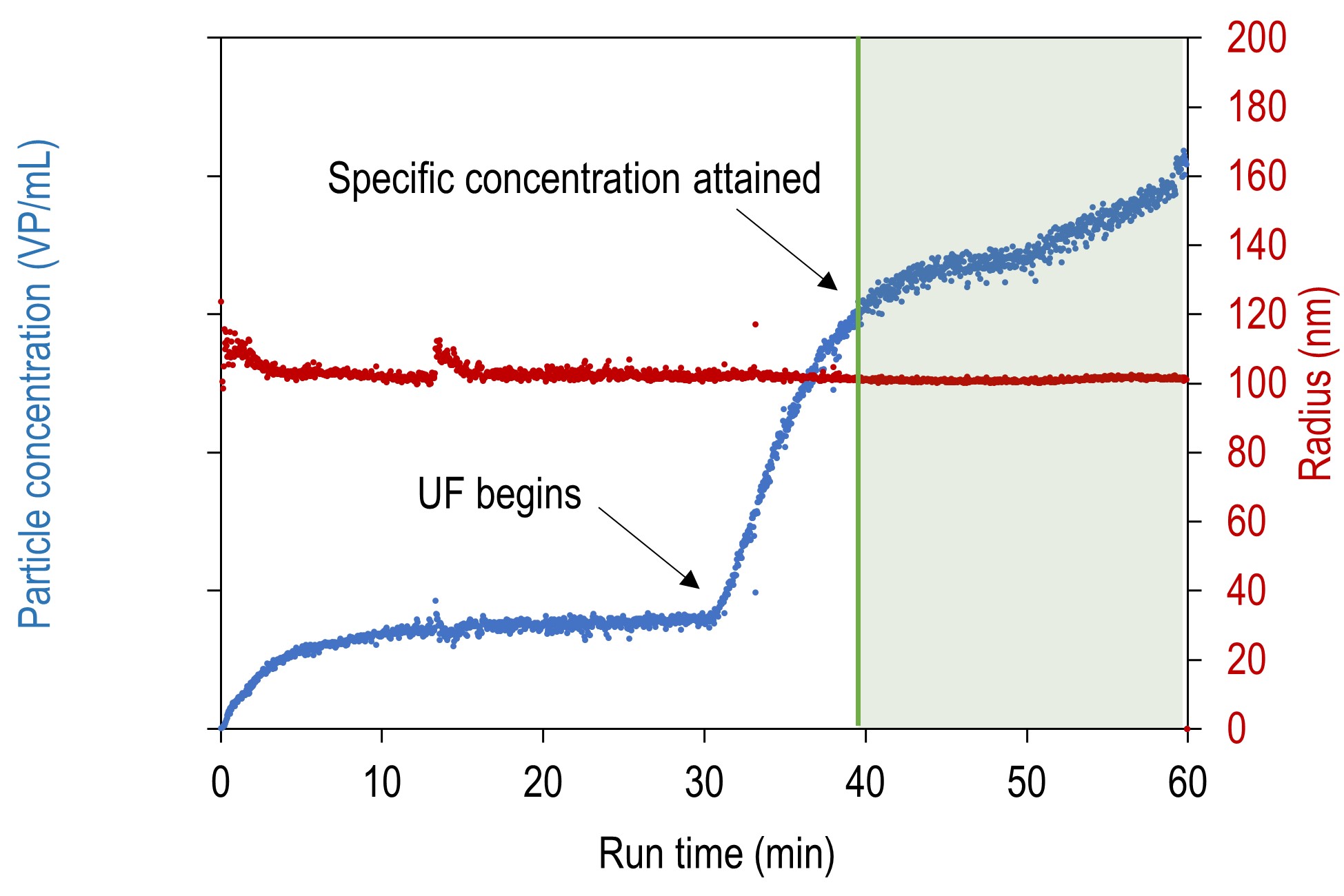

Ultrafiltration

A tangential flow filtration step for concentrating viral vectors can be controlled by an ultraDAWN set up to monitor particle concentration. The ultraDAWN is connected to the TFF flow path in an on-line configuration by a pump and continuously receives sample (which is subsequently returned to the TFF system). In OBSERVER™, the trigger is programmed to turn on when the concentration is above the specified end point, signaling to the control system to terminate the process.

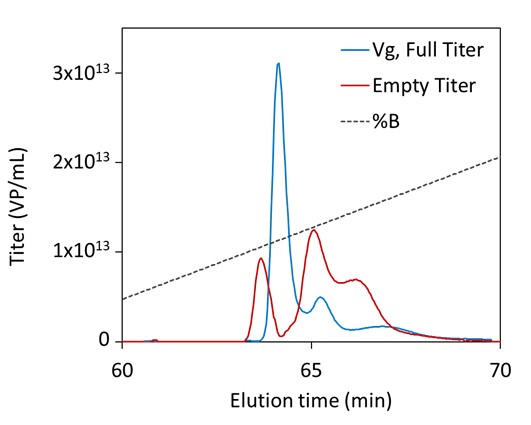

AAV capsid content and aggregation

Enrichment of full AAV vectors is often done by ion-exchange chromatography, where RT-MALS determines the full:total ratio Vg/Cp, empty and full titers and more. Increasing particle radius is useful in identifying aggregates. Here the trigger was set when Vg/Cp was between 0.4 and 1.2.

Liposome homogenization

RT-MALS monitors radius and triggers if outside the specified range, to divert out-of-spec product from contaminating the collection vessel. See AN8006: In-line monitoring of liposome size by RT-MALS.

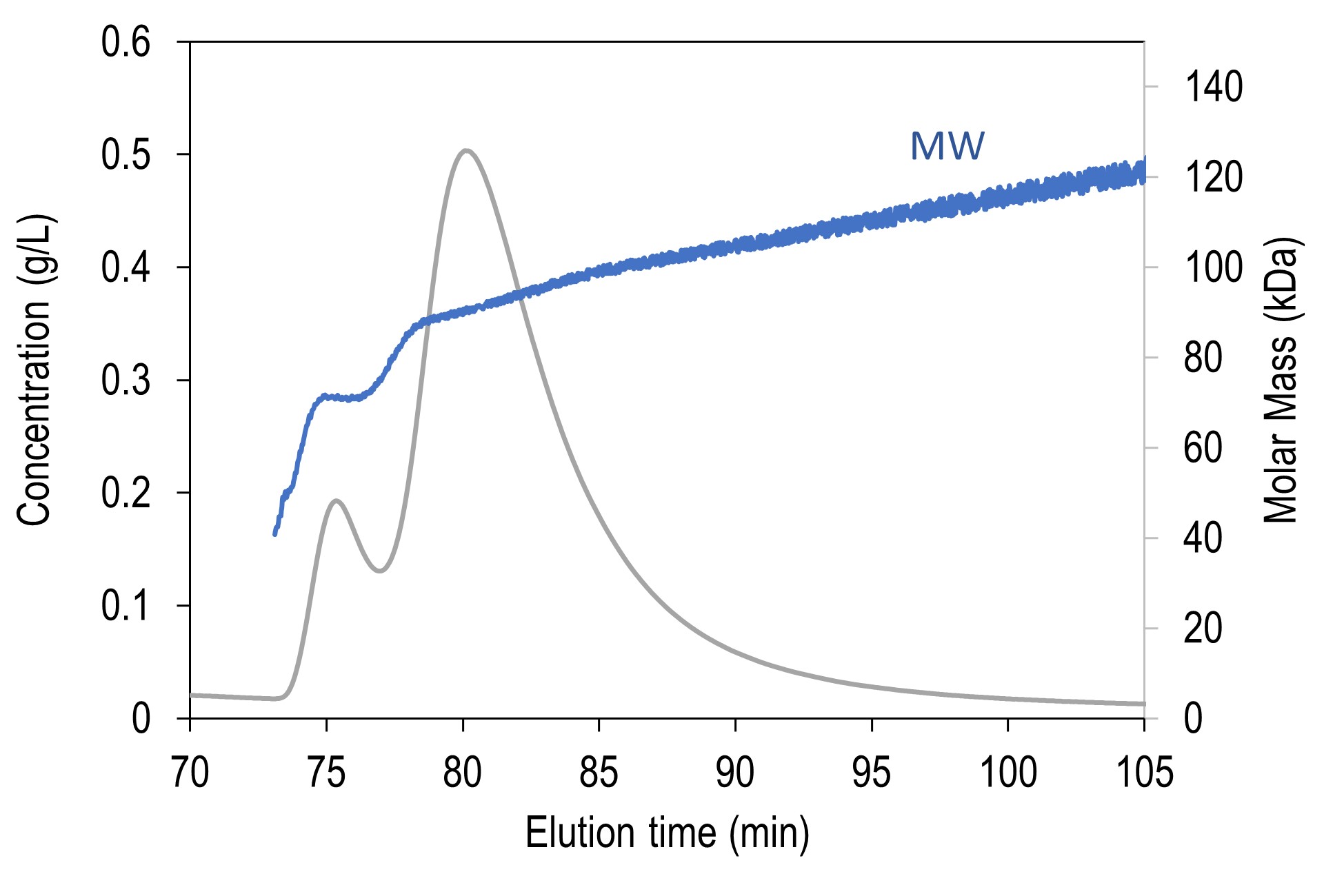

Protein bind-and-elute purification

Protein or nucleic acid molar mass can also be monitored reliably by RT-MALS in a bind-and-elute chromatographic polishing step if the eluting concentration is below ~ 2 g/L. Here a low-molecular-weight species is seen to elute first, then monomer with increasing aggregate levels reflected in Mw.

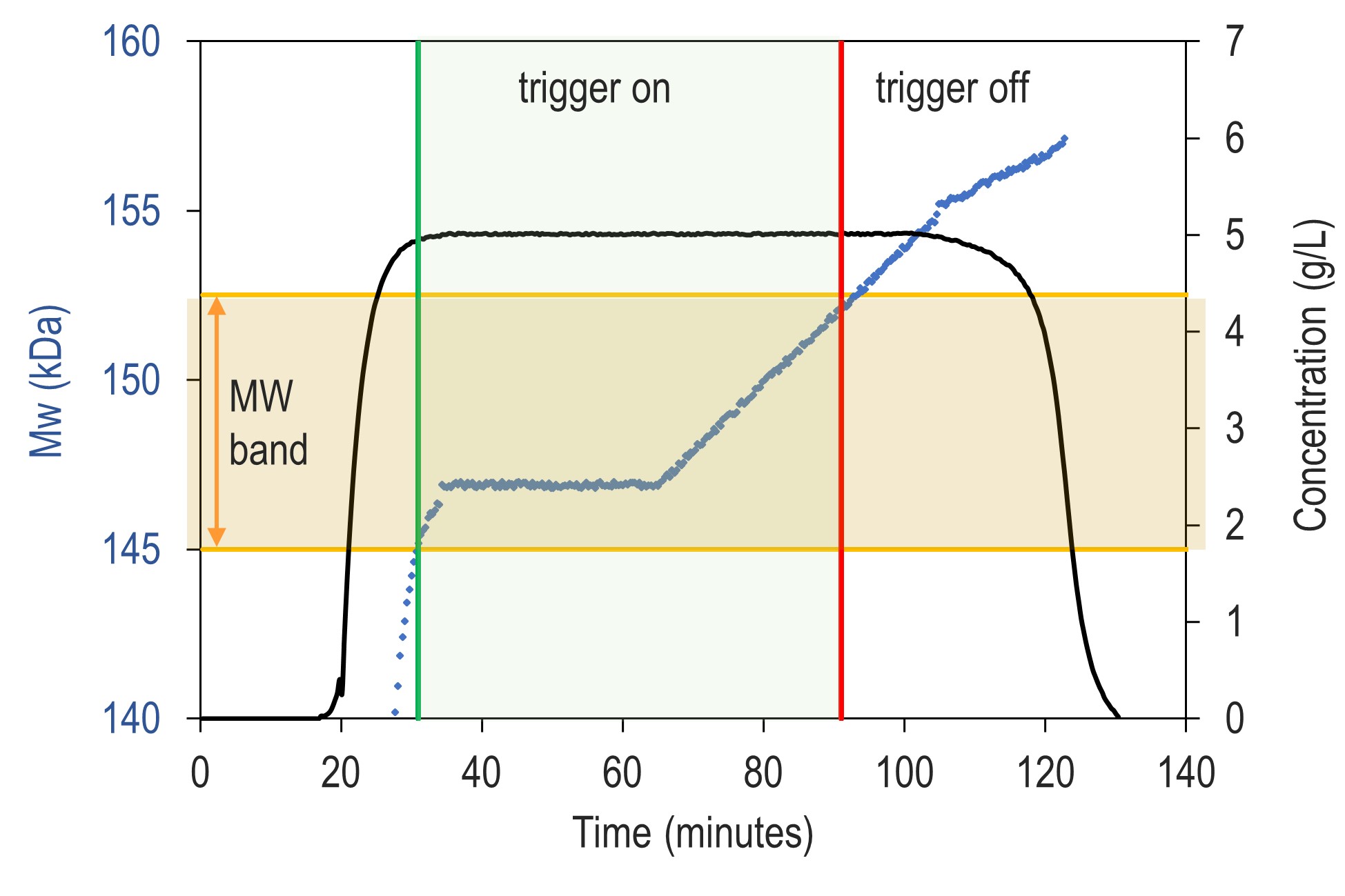

Protein flow-through purification

The weight-average molecular weight determined by RT-MALS can be used to estimate aggregate content in a polishing step using an ultraDAWN in-line with flow-through hydrophobic interaction chromatography. In this example with a 146.8 kDa mAb, OBSERVER’s trigger is programmed for a band between 145 and 152.5 kDa, the latter corresponding to 3.5% aggregate. The trigger turns on at 31 minutes and off at 91 minutes for overall aggregate content in the pool of 0.9%.

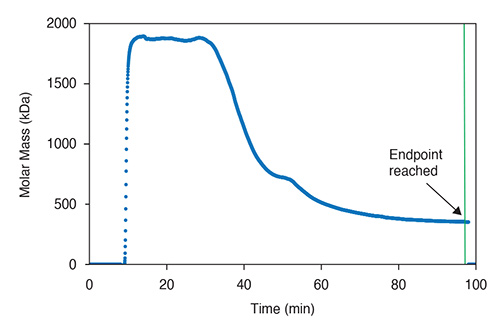

Polysaccharide depolymerization

In this process, hydrolysis of the polysaccharide must be quenched when it reaches the target molecular weight of 350 kDa. Using the on-line configuration, sample is continuously drawn from the reactor, diluted with buffer and delivered to the ultraDAWN. RT-MALS monitors molecular weight and sets the trigger when Mw is below the specified end point.

Click here for additional ultraDAWN applications.

OBSERVER RT-MALS software acquires real-time multi-angle light scattering data from ultraDAWN, then calculates and reports molar mass, radius, and/or particle concentration, up to 300 times each minute. When the RT-MALS results deviate from specifications or reach the process endpoint, OBSERVER can send a trigger to control the process, via analog voltage or digitally via OPC-UA. OBSERVER can also transmit real-time measurements for use by process control software via analog voltage or digitally via OPC-UA.

GMP requirements are fulfilled by operating OBSERVER as an OPC-UA server for an OPC-UA client such as SIPAT or DeltaV.

ASTRA™

ASTRA: ultraDAWN may be used with Wyatt’s well-known ASTRA software in post-processing mode. Data are collected during the process and analyzed shortly after the process is complete, in order to evaluate performance and assign molar mass, size or particle concentration values to fractions sampled over the process duration.

| Measurements | |

| Molar Mass Range | 1 kDa to 1 GDa1 |

| Size Range (Rg) | 10 nm to 250 nm1 |

| Size Range (Rh) | In flow mode, 0.5 nm to 300 nm2; batch mode 0.5 nm to 1 μm (requires WyattQELS™ DLS module). |

| Data Acquisition Rate | up to 300 measurements per minute |

| Accuracy | 5%3 |

| Repeatability | 2% |

| Temperature Options | Ambient Heated/Cooled (HC) -15 °C to +150 °C |

| Fluidics | |

| Solvent Compatibility | All-solvent compatible (aqueous and organic). Wetted materials are 316 stainless steel, fused silica and Kalrez. |

| Maximum Flow Rate | 150 mL/min @ 1 cP4 |

| Maximum Viscosity | 30 cP (when using HPLC pump in on-line configuration) |

| Optics | |

| MALS Detectors | High-gain, high dynamic range photodiodes at 18 detection angles. |

| Electronics | |

| Analog Inputs | 4 analog input lines for external signals from -10V to +10V |

| Analog Outputs | 4 analog output lines for sending trigger signals to process equipment |

| Other Inputs/Outputs | Alarm In, Alarm Out/Retransmit |

| Computer Interface | Ethernet |

| Front Panel Display | 10.1" (257 mm), capacitive high-resolution screen with multi-touch functionality, displays signals, graphs, instrument settings and diagnostics. May be used with gloves. |

| Dimensions | 58 cm (L) x 36 cm (W) x 26 cm (H) |

1Depending on dn/dc, the sample concentration and process conditions, this is typical.

2Upper limit depends on configuration and flow rate.

3Accuracy will decrease if sample or ambient temperature differs by more than ± 5 °C from the calibration temperature.

4Maximum flow rate decreases with viscosity.

Host PC requirements may be found in Computer Requirements.

Specifications subject to change without notice.

Other MALS Instruments

DAWN™ - The most sensitive MALS detector available, anywhere. Incorporates detectors at 18 angles to determine molar masses from 200 Da to 1 GDa and radii from 10 – 500 nm.

- Standard option: ambient temperature

- Heated/cooled option: -15 °C to +150 °C

- High-temperature option: ambient to +210 °C

The DAWN offers special options to handle fluorescent samples: fluorescence-blocking filters and an infrared, 785 nm laser.

miniDAWN™ - Second only to the DAWN in sensitivity. Incorporates detectors at 3 angles to determine molar masses from 200 Da to 10 MDa and radii from 10 – 50 nm. Ambient only.

microDAWN™ - The first MALS detector for UHPLC, with interdetector dispersion as low as 1.5 µL. Incorporates detectors at 3 angles to determine molar masses from 200 Da to 20 MDa and radii from 10 – 50 nm. Ambient only.