What are your recommendations for keeping a SEC-MALS system clean for as long as possible?

Introduction

Whether it’s a newly installed system or you’ve had your HPLC cleaned and your MALS instruments through their annual preventative maintenance, you want to keep your system clean. After all, the less time spent having to clean the instruments, the more uptime there is for experiments! Here are some tips that we use in our lab:

Tip 1

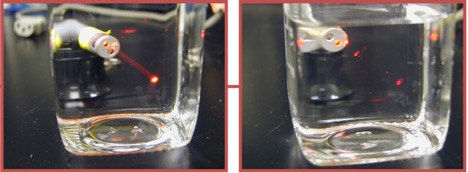

Make sure to always use fresh, filtered (0.1 µm) solvent. For an aqueous mobile phase, you’ll want to replace your solvent every few days or use an antibacterial agent such as sodium azide. It’s not always easy to see if a mobile phase is contaminated but with a laser pointer, you can assess your mobile phase as shown in the image to the right.

With a contaminated mobile phase, we can see the laser throughout the mobile phase due to scattering (left); however, with a clean mobile phase, we only see the laser when it is scattered at the glass interface (right). Be sure to never look at the beam directly though!

Tip 2

Even with antibacterial agents, you should change your mobile phase every few weeks to be safe. You can also use a device like our Solaris™ which kills bacteria in the buffer with UV light.

Tip 3

You’ll also need to replace aging or contaminated columns. Pressure changes on your HPLC column will dislodge particles, dust, and even column packing material (column shedding) that will increase baseline noise in the LS detector. You can prolong the lifetime of your column by changing the flow rate slowly (0.1 mL/min per minute or less) and always equilibrating your column for 12-24 hours before an experiment. We also recommend adding a guard column in front of your column for added protection. When installing a column for the first time, you should bypass all detectors and flush the column to waste for 24 hours before hooking it up to your detectors.

Even with the best precautions, particles can get into the mobile phase. A Wyatt inline filter will filter out particles in the solvent or shed by an HPLC pump. Our inline filter membranes range from 0.025 to 0.2 μm. In contrast, the built-in filters in HPLC systems only remove particles of 10-20 μm size, which is not sufficient for light scattering measurements. An inline filter comes before the injector, so it won’t filter your sample but will protect your columns. When used with a recycling solvent system like the Orbit™, inline filters help polish the system and keep it clean by filtering out particles shed by the column. Due to the high pressures of UHPLC systems, inline filters are not recommended for microDAWN™ systems.

Conclusion

You can find more technical notes, tutorials and manuals on our Customer Support Center. Simply go to https://www.wyatt.com/support/ and login or create an account. Do you have a question? Contact our experts here in Customer Support. We’re happy to help! Call +1 (805) 681-9009 option 4 or email support@wyatt.com.