VISION

Intelligent design, operation and analysis for field-flow fractionation

Flatten the learning curve and increase your productivity. Wyatt offers unmatched software tools for designing, performing and analyzing FFF-MALS experiments.

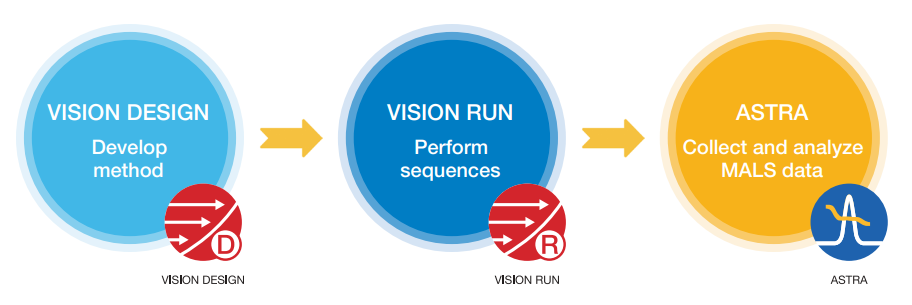

VISION offers a seamless workflow in a few simple steps, starting with developing and optimizing the FFF method in silico, then running a sample sequence, followed by data processing, refining the separation method, reporting and consolidating the data files in projects.

VISION coordinates data collection in ASTRA™, the most powerful and versatile software available for the characterization of macromolecules and nanoparticles via multi-angle and dynamic light scattering.

VISION offers an optional 21 CFR Part 11 compliant security and database package for use in GMP and GLP laboratories, and synchronizes data acquisition with ASTRA 21 CFR Part 11 compliance package.

The brains behind FFF

VISION software is the intelligent human interface to an FFF-MALS system built on Wyatt Technology’s Eclipse™ FFF instrument and DAWN™ MALS instrument. VISION comprises two primary modules: VISION DESIGN™ for in silico method design and optimization and VISION RUN™ for running FFF methods.

VISION

VISION software is the central hub for your FFF-MALS system built on the Eclipse FFF instrument and DAWN MALS instrument.

VISION software is the central hub for your FFF-MALS system built on the Eclipse FFF instrument and DAWN MALS instrument.

VISION DESIGN

Combines simplified, rationalized FFF method development with FFF data analysis to optimize separations based on FFF theory.

Combines simplified, rationalized FFF method development with FFF data analysis to optimize separations based on FFF theory.

VISION RUN

Seamlessly coordinates the pump and autosampler front-end with the Eclipse, detectors and ASTRA, and records FFF, electrical and digital UV signals for diagnostics and analysis in VISION DESIGN and ASTRA.

Seamlessly coordinates the pump and autosampler front-end with the Eclipse, detectors and ASTRA, and records FFF, electrical and digital UV signals for diagnostics and analysis in VISION DESIGN and ASTRA.

ASTRA

Flagship software for comprehensive characterization of macromolecules and nanoparticles by SEC/FFF-MALS. Acquires, analyzes and reports measurements from multi-angle light scattering, dynamic light scattering, UV/Vis, dRI and differential viscometry detectors. Building on over 40 years of light scattering research, ASTRA includes an unrivaled range of analysis features.

Flagship software for comprehensive characterization of macromolecules and nanoparticles by SEC/FFF-MALS. Acquires, analyzes and reports measurements from multi-angle light scattering, dynamic light scattering, UV/Vis, dRI and differential viscometry detectors. Building on over 40 years of light scattering research, ASTRA includes an unrivaled range of analysis features.

Effortless method development

The flexibility of FFF allows users to achieve excellent separations for most applications, but in some cases finding the optimal method for the separation run may require tedious trial-and-error.

The flexibility of FFF allows users to achieve excellent separations for most applications, but in some cases finding the optimal method for the separation run may require tedious trial-and-error.

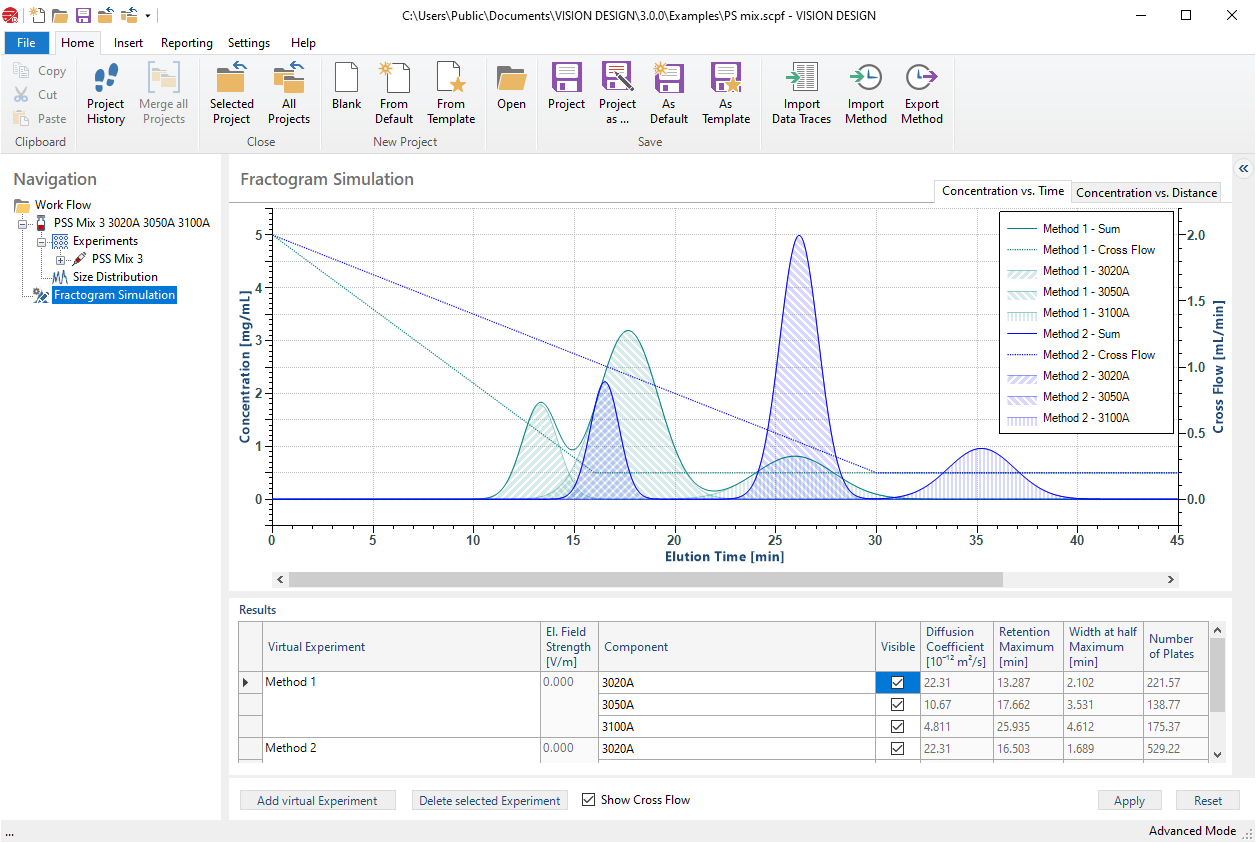

VISION DESIGN is an indispensable tool for FFF method development which utilizes in-silico, "virtual" experiments based on FFF theory to eliminate most of the time and effort required for FFF method development.

Enter the estimated particle sizes of your sample of interest, select your channel and predict your fractogram based on:

- Channel-flow rates

- Cross-flow profiles

- Spacer heights

The final design can be transferred in a click to VISION RUN to run and test your method.

The results of a physical experiment can then be fed back into VISION DESIGN to further refine the method. Usually a single test run will give VISION DESIGN the information it needs to help you fully optimize your method.

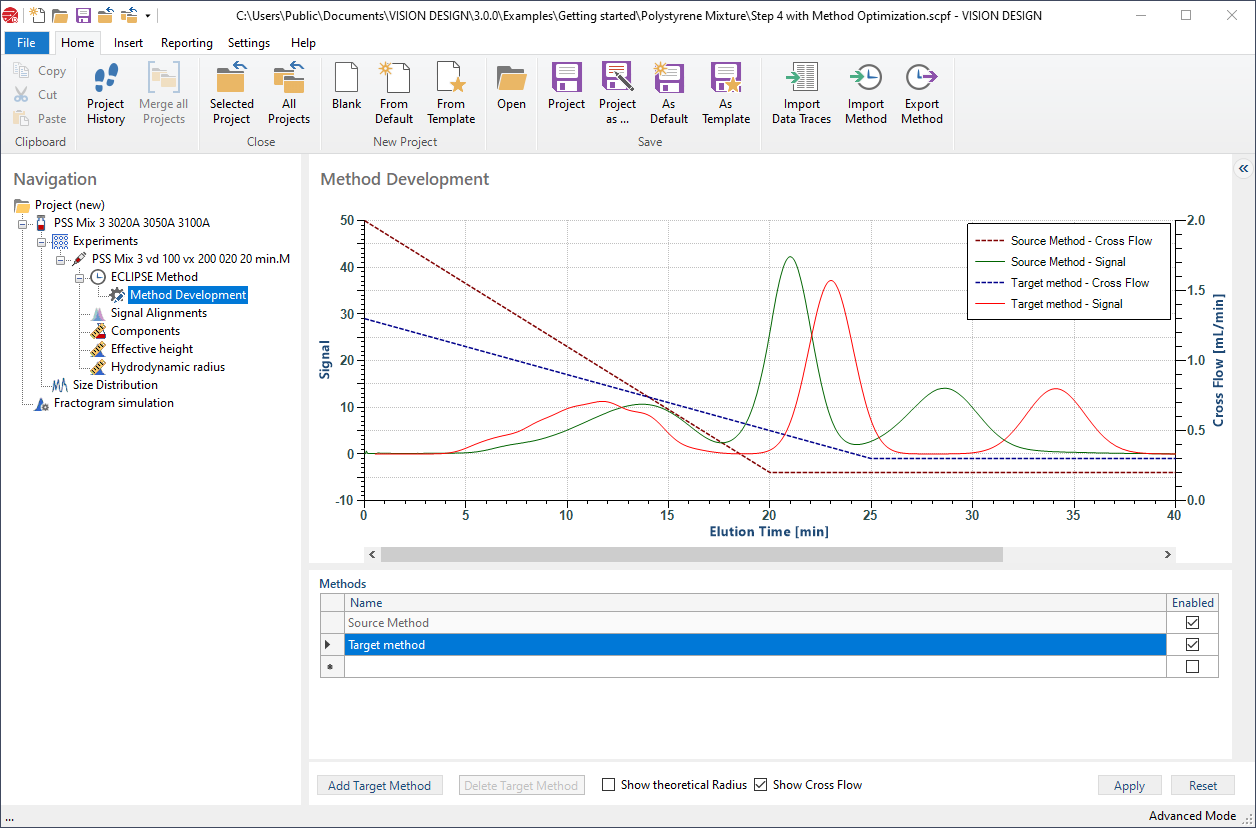

From virtual to method

VISION DESIGN immediately displays the predicted fractogram using fundamental FFF theory to calculate retention times, including the effects of band broadening and dilution of the sample in the FFF channel. It only takes a few minutes to explore the effect of different cross-flow rates and timings to improve resolution and find the best method - all from the comfort of your desk.

The example to the right shows the process for optimizing a nanoparticle separation.

The green experiment is the result of a default method for separating a sample containing three nanoparticle sizes. The dashed green line shows the cross-flow gradient used, and the solid green line is the measured concentration signal.

The blue experiment is the result of simulations tested to improve the resolution. With a modified cross-flow gradient, the peaks are expected to exhibit baseline resolution.

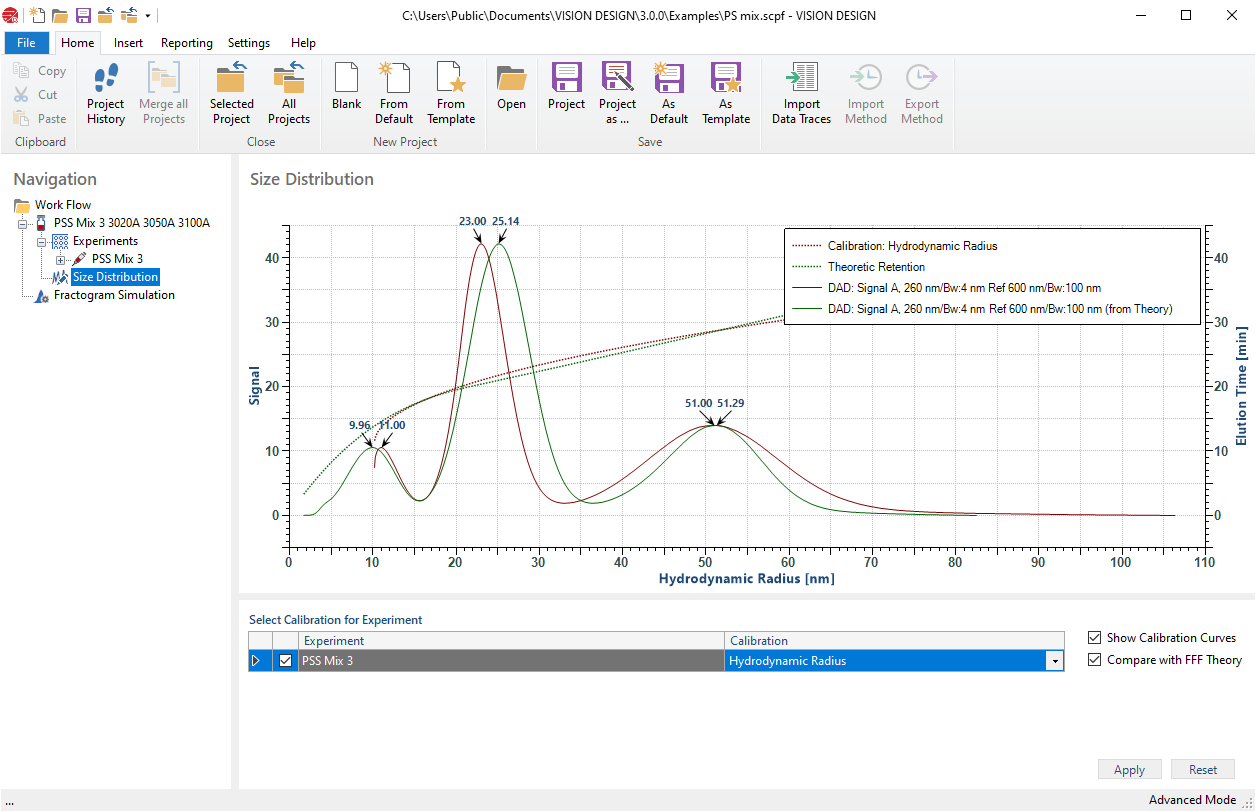

Particle size distributions

An additional benefit of VISION DESIGN is the analysis of fractograms collected in VISION RUN to determine size distributions based on FFF retention time, even without the use of light scattering data.

Determine the hydrodynamic radius (Rh) and its distribution from a calculation based on fundamental FFF theory or a calibration with reference standards.

The graph shows size distributions of a polystyrene latex mix reference standard calibration and comparison with FFF theory.

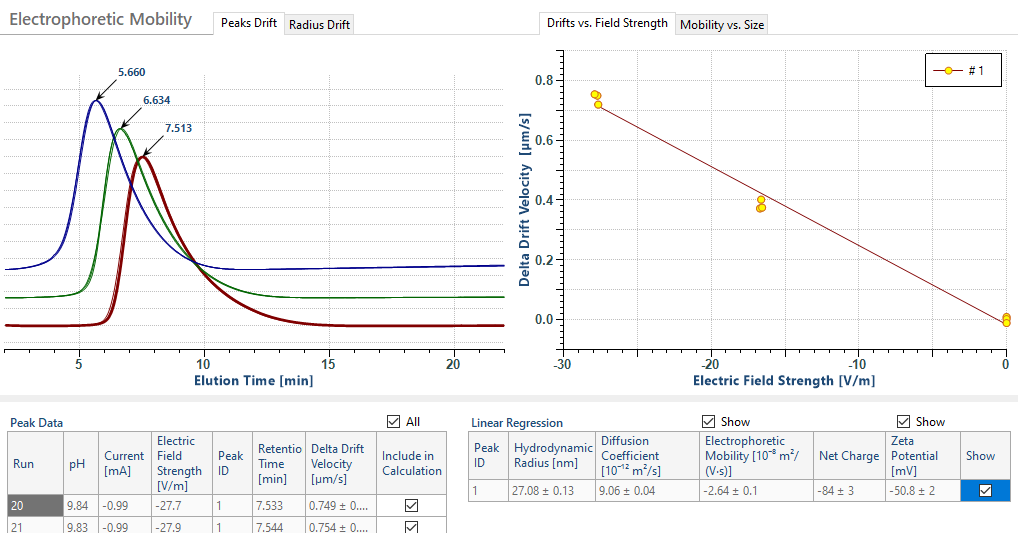

Electrophoretic mobility and zeta potential

Electrical/asymmetric-flow field-flow fractionation (EAF4) separates by both size and particle charge to determine zeta potential distributions, even of multimodal and polydisperse populations.

VISION calculates zeta potential and electrophoretic mobility from EAF4 measurements made with different applied electrical fields. VISION DESIGN offers fully automated processing plus determination of peak retention time and its shift with the electrical field.

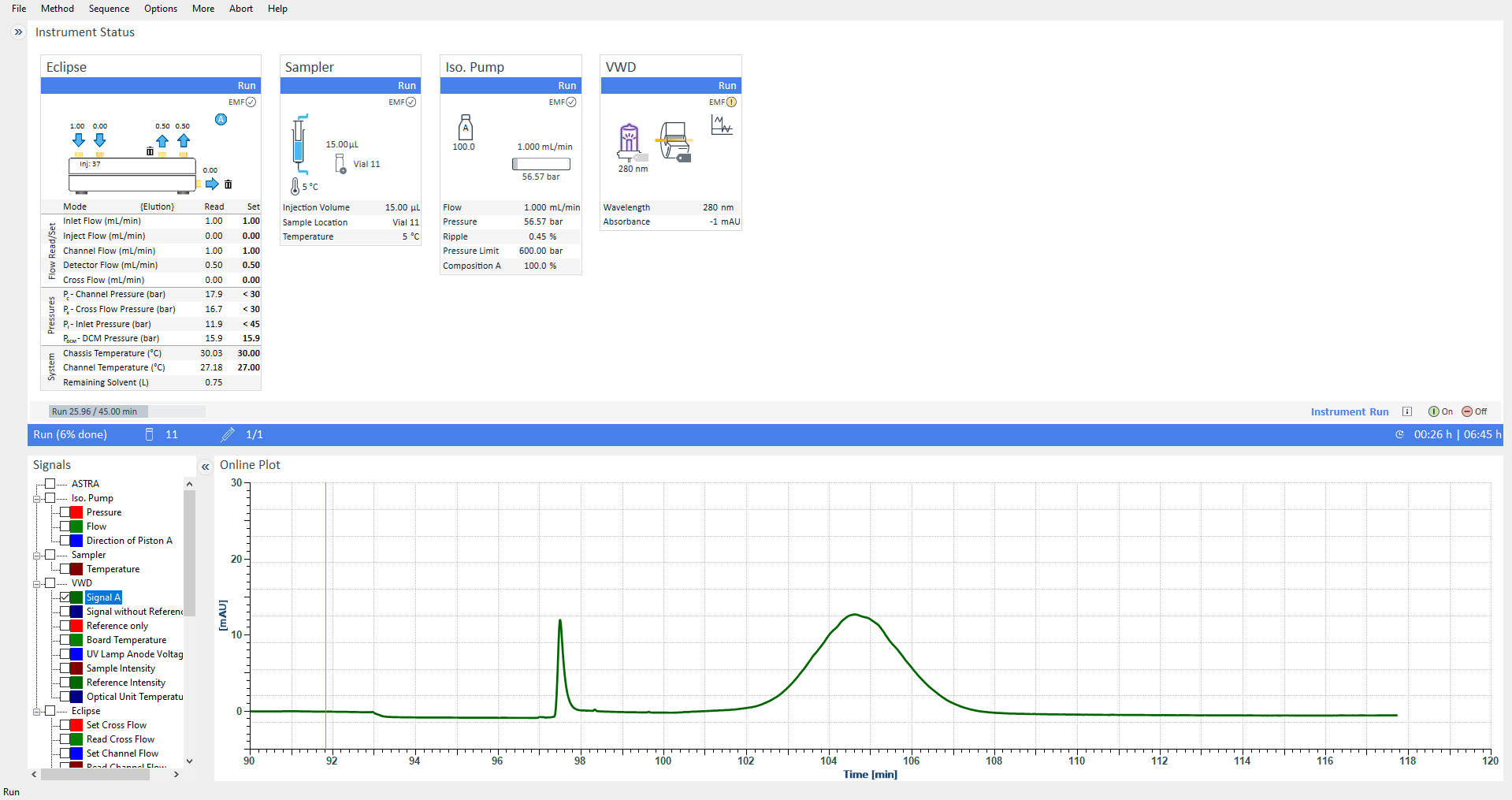

Enter the Cockpit

VISION RUN is a sophisticated control center for the Eclipse FFF system for maximum productivity.

VISION RUN is a sophisticated control center for the Eclipse FFF system for maximum productivity.

VISION RUN uses the ICF instrument control framework for Agilent® modules from the 1260 series. The complete feature sets of autosamplers, isocratic or quaternary pumps, UV detectors, fluorescence detectors and fraction collectors are supported.

The dashboard shows instrument status with instrument configurations, settings, real-time status and signal display and sample sequences.

Status information from the Eclipse instrument’s Health Indicators are displayed; should any warnings come up, you will receive actionable recommendations.

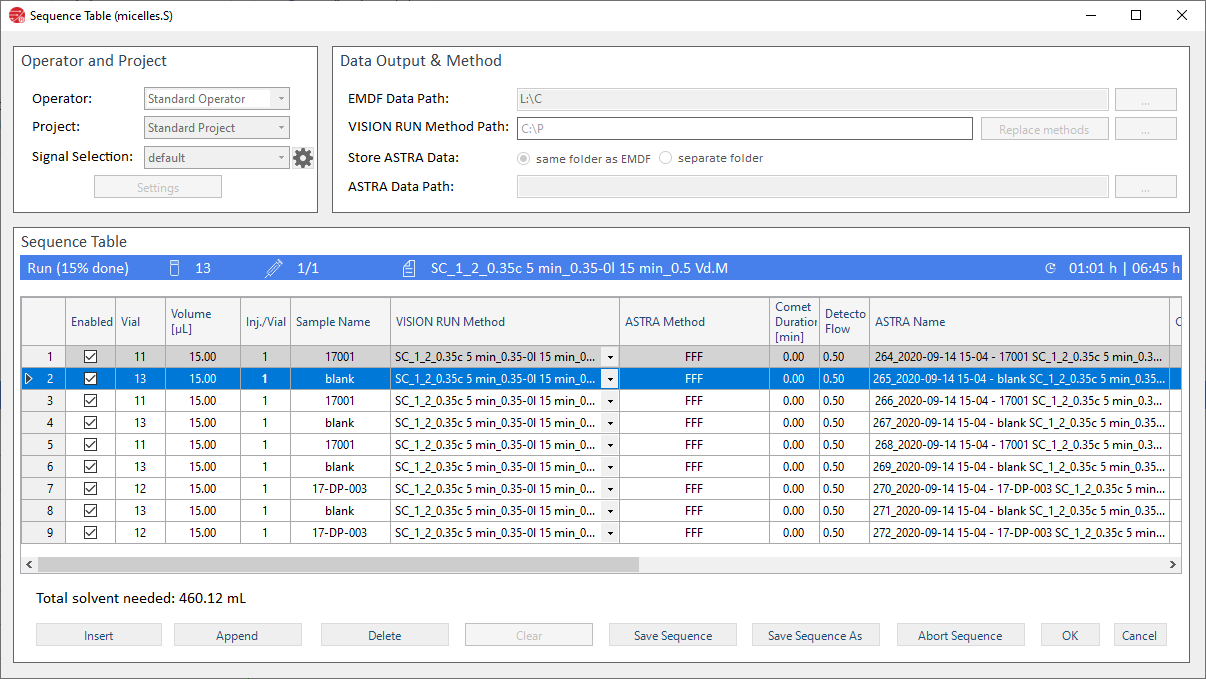

Automated Sample Sequences

Once a sample sequence table is defined, VISION RUN will coordinate FFF operation and MALS analysis methods. Samples can be added to sequences on the fly for maximum convenience.

Digital signal acquisition

VISION RUN transfers UV/VIS signals directly to ASTRA. Set UV parameters and acquire all signals digitally, without any external cabling required. Select up to two UV channels for analysis in ASTRA – even post-collection.

VISION offers an optional 21 CFR Part 11 compliance package, including IQ/OQ documents and procedures, which are described below and more fully in the 21 CFR Part 11 White Paper. VISION SP launches and synchronizes with ASTRA SP and employs a secure, joint SQL database for VISION and ASTRA data.

Data Safety and Integrity

21 CFR Part 11 requires that electronic data be persistent, and that any changes to the data be recorded in an audit trail. VISION employs two methods to ensure this:

- All data and audit trails generated by VISION RUN under Security Pack mode are stored in a secure, ODBC-compliant database. The database can be networked for automatic back-up by the IT department. This ensures that data will not be lost, and that any changes to the data will be associated with an audit trail in the same database.

- Encrypted checksums: Each entry in the database has an encrypted checksum. VISION uses this checksum to verify that the data being read from the database has not changed since it was last written, and notify the user of any data corruption or any attempt to alter the data.

User Security

In a compliant installation, system access is limited to authorized individuals. Wyatt software leverages the Microsoft Windows security system to provide user authentication:

- Secure login - In order to run VISION with Security Pack enabled, users must enter a unique user ID and password. Logins, login attempts, and logouts are all recorded in the ODBC-compliant database.

- Microsoft Windows user accounts and groups are leveraged for security. System administrators create four specific security groups, then associate existing Microsoft Windows users with these groups. The Microsoft Windows user accounts are then used to log in.

- It is possible to set up VISION security groups in the Active Directory, such that network-authenticated accounts can be given appropriate privileges. One domain-level user account can then be used to log in to any instance of VISION on the network.

Privilege levels

User accounts can have one of four privilege levels:

- Administrator - Administrators have rights to perform all actions, including changing database connections and deleting data.

- Researcher - Researchers can create and run new methods, change instrument configuration settings, and export and import data from the database.

- Technician - Technicians can only run predefined methods set up by a Researcher. Technicians can collect data and perform simple processing, but cannot change any configuration settings.

- Guest - Guests have read-only privileges to view audit trails and data.

Audit Trails

VISION provides two levels of audit trail to independently record all operator actions that create, modify, or delete electronic records. Each entry in the audit trail is time-stamped, and records the operator performing the actions, as well as the computer where the actions are performed.

System log

The system log is always associated with the database where the data is stored. The system log records actions such as:

- Logins, login attempts, and logouts

- Data creation, modification, and deletion

- Database connections and disconnections

- Import and export of data from the database

Experiment log

Each FFF method, sequence and configuration has a separate log that records all actions performed. The logs are always linked with their respective method, sequence or configuration, and cannot be reset. The logs record actions such as:

- Changes to instrument configuration settings

- Changes to sequences

- Changes to methods

- Collection of data

Electronic Signatures

Electronic signatures can be executed on any data collected. As such, electronic signatures will be performed in ASTRA in Security Pack mode. Please see the ASTRA product page for more details.

Enforcing Permitted Sequences

Ideally, a 21 CFR Part 11 compliant application should be usable for quality assurance in a manufacturing process. To meet this goal, it is necessary that the application support "operational system checks to enforce permitted sequencing of steps and events". In other words, it should be possible for a technician in quality assurance to run the application with minimal input and limited possibility to affect the results through incorrect decisions.

VISION SP has strong support for enforcing permitted sequences through the methods. A user with Researcher privilege level can create a new experiment, and then save it as a Method. A user with Technician privilege level can only use the Method to collect and analyze data, and cannot make changes to the Method configuration, analysis, or results reporting.

With method and sequences technology, VISION supports moving macromolecular and nanoparticle characterization into everyday manufacturing and quality assurance applications.

Human Readable Records

All data that VISION generates are made available to the user in human readable form. Using powerful data export and presentation capabilities, all data can graphed, shown in tables, or exported to text.

Validation

Incoming Qualification and Operational Qualification documents are provided with VISION SP software, ensuring validation at the lab site.

In addition, Wyatt’s software products are completely validated products:

- All software development is executed under a formal quality system, using a standard software lifecycle model.

- Documented testing and traceability is performed to demonstrate accuracy, reliability, and consistent intended performance.

- The ability to discern altered or invalid records is built in.

We welcome audits of the software development and maintenance process by customers' qualified auditors.

Host Computer Requirements

Please see Host Computer Requirements for details of the computer hardware required by VISION.

Click to enlarge image.

Click to enlarge image. Click to enlarge image.

Click to enlarge image. Click to enlarge image.

Click to enlarge image. Click to enlarge image.

Click to enlarge image. Click to enlarge image.

Click to enlarge image. Click to enlarge image.

Click to enlarge image.